Researchers have discovered that hydrogen substitution can boost the performance of transition metal oxides and limit their high thermal conductivity.

Today, more than half of the total energy produced from fossil fuels is discarded as waste heat, which accelerates global warming. To minimise this, hydrogen substitution has been pioneered as a technology for generating eco-friendly electricity from waste heat.

Converting waste heat into more useful, sustainable forms of energy, such as electricity, would minimise fuel consumption and reduce the planet’s carbon footprint.

In the new study, published in Advanced Functional Materials, the Tokyo Institute of Technology team discovered that hydrogen substitution can tackle the high thermal conductivity of metal oxides.

Overcoming the limitations of a high thermal conductivity

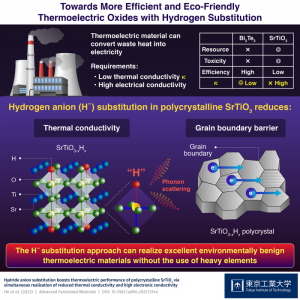

For efficient conversion, a thermoelectric material must have a high conversion efficiency (ZT). So far, realising a high ZT has been possible only with the use of heavy elements like lead, bismuth, and tellurium. However, the use of rare, expensive, and environmentally toxic elements such as these has limited the large-scale application of thermoelectric energy conversion.

To overcome these issues, transition metal oxides based on platforms such as SrTiO3 have emerged as a more inexpensive and benign alternative. However, their ZT is typically limited by a high thermal conductivity, because for this, the temperature across the material becomes uniform more quickly, and the lowered temperature difference – the driving force behind the thermoelectric conversion – causes electric power generation to decrease too.

In their paper, the researchers state: “Hydrogen substitution offers a new approach for ZT enhancement in thermoelectric materials without utilising heavy elements because the hydrogen substitution does not form a grain boundary potential barrier and thus suppresses electron scattering.”

Conventionally, the use of light elements is expected to increase the thermal conductivity originating from lattice vibration, leading to the adoption of heavy elements to reduce the lattice vibration. In contrast, the team discovered that this could be reduced to less than half its original value by hydrogen substitution.

The process is vital for developing next-generation, sustainable materials

The team stated that the mechanism underlying their observation showed that substituting a portion of the oxygen anions with substituted hydrogen anions yielding compounds of the form SrTiO3−xHx, results in a mixture comprising a strong Ti-O bond and a weak Ti-H bond. In turn, hydrogen substitution largely decreased the lattice vibration, which is essential for sustainability.

The team also found that SrTiO3−xHx polycrystals exhibit high electron mobility comparable to that of single-crystal materials without any deterioration in electron conduction across grain boundaries. Based on these two effects, a low thermal conductivity and a high electrical output can co-exist, which means that the thermoelectric conversion efficiency of the polycrystal is improved.

Overall, these findings can open doors to innovative strategies for developing next-generation thermoelectric materials. Moreover, further studies in this field could lead to the widespread adoption of thermoelectric conversion technology so that waste heat can be converted into eco-friendly, useful forms of energy.

Associate Professor Takayoshi Katase, who led the study, concluded: “In the future, the hydrogen substitution approach would realise excellent environmentally benign thermoelectric materials that do not require the use of heavy elements.”