Nissan Motor Corporation has revealed it is trialling a bioethanol-powered solid oxide fuel cell to drive the company’s EV production.

The cutting-edge solid oxide fuel cell is capable of high-efficiency power generation and will potentially revolutionise Nissan’s production plants, enabling them to become carbon neutral.

Nissan’s goal is to achieve carbon neutrality across all operations and fully electrify plants by 2050, generating all electricity from renewable sources and alternative fuels.

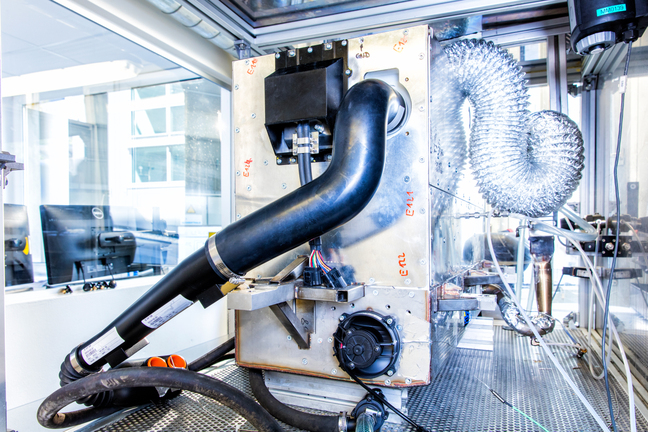

Trials of the solid oxide fuel cell system are now underway at the company’s Tochigi Plant in Japan, aiming to boost power generation capacity toward full-scale operation from 2030.

Kazuhiko Murata, corporate vice president responsible for Powertrain Production Engineering and Development, commented: “There are major changes occurring in the transition from the internal combustion engine to electric vehicles.

“Nissan is taking up various technological development challenges in new areas, and solid oxide fuel cell power generation is one of our strengths.

“We will continue to contribute to the promotion of electrification and efforts toward carbon neutrality with Nissan-unique, innovative technologies.”

How do solid oxide fuel cells work?

Nissan became the first automaker in the world to develop a vehicular propulsion system powered by a solid oxide fuel cell run by bioethanol in 2016.

Now, the company is leveraging this technology to create large-scale stationary power generation systems.

Solid oxide fuel cells offer a seamless integration with high-temperature reformers, facilitating the generation of electricity through the conversion of hydrogen derived from diverse fuel sources like ethanol, natural gas, and LP gas reacting with oxygen.

Operating at elevated temperatures fosters robust catalytic activity, enabling solid oxide fuel cells to achieve an impressive 70% power generation efficiency, outperforming polymer electrolyte fuel cells (PEFCs) which stand at 60%.

Looking ahead, advancements in the development of metal-supported cells within the solid oxide fuel cell stack promise to enhance cell durability significantly.

This innovation will lead to reduced start-up and shutdown times, as well as the ability to swiftly respond to fluctuations in output demands. These advancements pave the way for efficient solid oxide fuel cell system operation in conjunction with renewable energy sources in the foreseeable future.

Securing a sustainable bioethanol supply

The stationary power generation system will rely on bioethanol derived from sorghum, a product of collaborative development efforts with Binex Inc.

Fuel procurement will be facilitated through Binex, and this aspect of the system will begin operations in 2025.

Sorghum is an annual herbaceous plant, rapidly maturing in about three months, allowing for multiple yearly harvests under favourable conditions.

Its versatility in cold and arid climates enables cultivation across various regions and soil types.

The stem serves as ethanol feedstock, while the grain is utilised for food, avoiding conflicts with food production. Additionally, stem waste can be repurposed for biomass power generation.

While sorghum bioethanol emits CO2 during solid oxide fuel cell power generation, the carbon dioxide released is offset by absorption during the sorghum growth phase.

This process contributes to achieving a carbon-neutral cycle, effectively minimising CO2 emissions.