AML’s technologies enable the use of lower-cost materials and improve performance and lower the cost of magnet-based products.

The Advanced Magnet Lab (AML), located in Melbourne, Florida, is reinventing the magnet supply chain with its innovative magnet technology.

AML addresses lowering the cost of raw materials, lowering the cost of manufacturing, and increasing the performance and cost of end-use products, such as motors and generators.

PM-Wire™ technology: A unique solution to reinvent the magnet supply chain

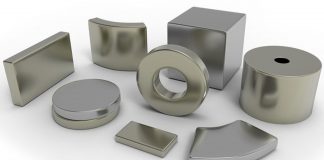

AML’s technology approach, known as PM-Wire™, is unique. Unlike the conventional methods, AML’s approach is not to cut small-piece parts of magnet blocks and sell commoditised magnets.

PM-Wire magnets are designed and manufactured for optimum size, shape, and magnetisation. The technology uses a ‘wire-like’ manufacturing process where all the critical process parameters can be adjusted and precisely maintained for any magnet alloy type – including non-rare-earth materials.

AML’s approach to the magnet market is unique. The company focuses on what matters, the magnet-based end-use product, and optimising them for performance and cost.

PM-Wire can be used with all existing sintered magnet alloys, opening up new markets for non-sintered designs and non-rare earth metals. Motor designs can now be fully optimised for performance, including weight, torque, operating temperature, and ease of assembly.

The PM-Wire impact

Three real-world examples of how PM-Wire can improve the performance and lower the cost of motors to reinvent the magnet supply chain include:

- PM-AXIAL™: ‘Plug-and-Play’ replacing conventional the North-South pole configuration in industrial motors with a solution providing Halbach array performance, increases operational temperature by 20%, eliminates iron in the rotor and reduces the rotor overwrap/containment thickness by 50%;

- PM-360™: ‘Plug-and-Play’ replaces 2,750 Halbach arranged magnets in an electric vehicle motor design with eight PM-360 rings and eliminates the need to cool the motor rotor actively; and

- PM-AXIAL™: Motor topology, which can achieve the U.S. Department of Energy’s electrical vehicle motor power density goals of 50 KW/L with 70% lower rare earth content today and no rare-earth content materials in the future.

AREAS OF INTEREST

- Creating a new and stable magnet supply chain;

- Building better magnets in the US;

- Innovative solutions for the design, manufacturing, and application of magnets; and

- Low-cost products with increased performance.