QMC Quantum Minerals Corp, a mineral development company with three established world-class mineral-rich projects in Canada, are working to develop our Irgon Lithium Mine, Rocky Lake and Namew Lake projects to supply lithium, copper and other metals for the electric vehicle and charging station markets.

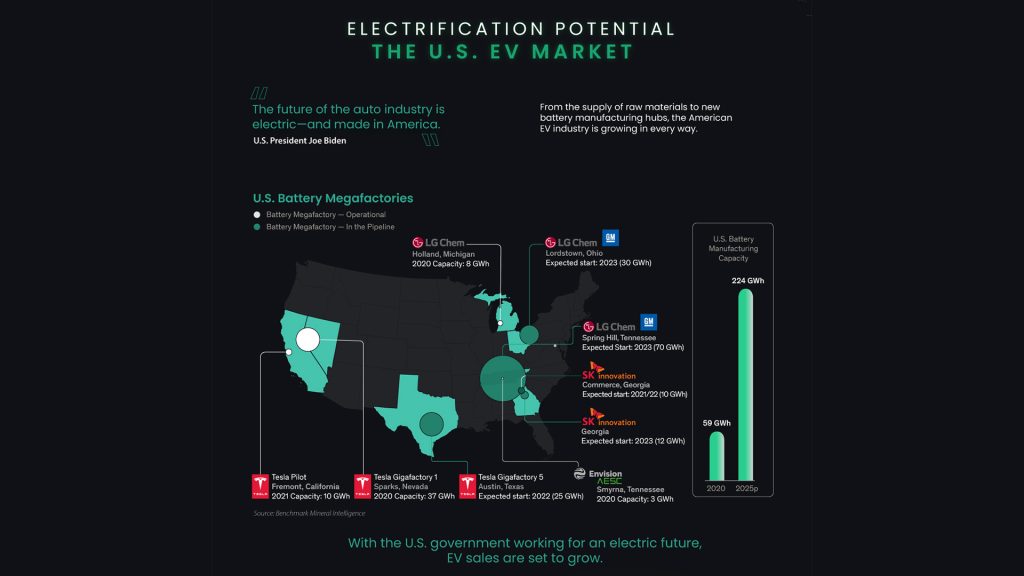

As President Biden and many world governments set new targets for the transition to electric vehicles (EVs), attention focuses on how to meet these ambitions. For instance, President Biden hopes that EVs will make up half of all new auto sales by 2030, highlighting the race to secure relevant stable and secure domestic supply chains for battery materials. With support from major EV manufacturers to achieve EV sales of 40-50% of annual US volumes by 2030, there is now a realisation that battery manufacturing is the cornerstone to success and securing battery material supply chains is a fundamental requirement.

As major auto manufacturers invest in plants, QMC Quantum Minerals Corp has an excellent opportunity to supply the North American electric vehicle and battery manufacturing markets. We have recently seen that:

- General Motors investing $3bn to make EVs in Michigan;

- Toyota Motor Corp. Is making a $1.25bn investment to build a new battery plant in North Carolina;

- Ford Motor Company investing $11bn to build three battery plants in Kentucky and Tennessee along with an electric-truck plant, and $1.8bn retooling of its Oakville, Ontario assembly plant; and

- Fiat-Chrysler investing $1.5bn to upgrade its Windsor, Ontario assembly plant.

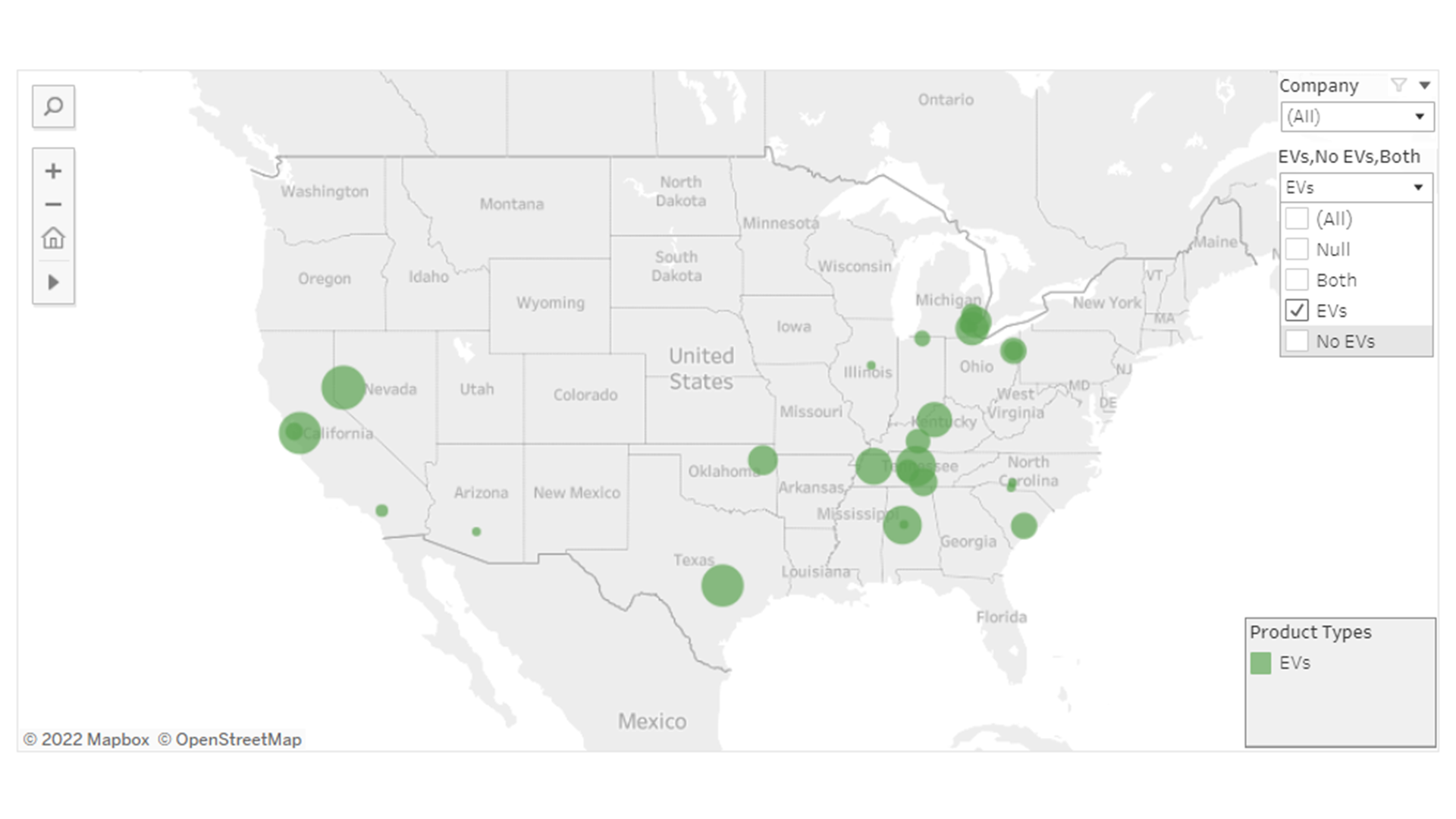

In addition to the investment in the auto plants mentioned above:

- Volkswagen AG has an EV production in Tennessee;

- Polestar manufactures its fully EVs in South Carolina;

- Tesla is aiming to have a new factory in Texas;

- Lucid Group manufactures its vehicles in Arizona; and

- LG Chemical has battery plants in Ohio and Tennessee.

North American located battery plants need to be less reliant on Chinese and oversees lithium supplies.

Quantum Minerals Corp: High-grade lithium to support battery manufacturing

As a mineral development company with three established world-class mineral-rich projects in Canada, we are working to develop the supply of lithium and other precious metals for the future of EVs.

Our flagship project is the Irgon Lithium Mine, an advanced stage, near-term production lithium project in the Canadian province of Manitoba. It is located just 20km from the most productive lithium mine in North America. The Irgon Lithium Mine boasts a historical economic resource of 1.2 million tonnes grading 1.51% Li2O (est. 236,000 tonnes of 6% lithium concentrate) with the potential for over 5 million tonnes ($3bn+ of lithium concentrate).

The location of the Irgon lithium mine also has several advantages:

- Provincial Highway 314 transects the property;

- Proximity to rail, water and electricity;

- Sinomine’s processing facility 20km to the South can process ore;

- Ore can also be shipped to China for processing;

- Additional dikes along the North and South of the Irgon Dike increase historical tonnage;

- Mining friendly province of Manitoba; and

- Additional minerals such as tantalum ($150/kg) and caesium are available in the same ore.

Manitoba has been one of the world’s most productive mining regions for copper, zinc, nickel, and gold for the past 100 years, accounting for approximately 6% of Canada’s annual copper production, 12% of nickel and 24% of zinc production.

Our Rocky Lake and Namew Lake projects, located in Manitoba’s world-renowned Flin Flon mining district, are home to volcanogenic massive sulphide (VMS) deposits, one of the richest sources of metals, including copper, lead, gold, and zinc globally. Currently, global metal production from VMS deposits accounts for 22% of zinc, 9.7% of lead, 6% of copper, 8.7% of silver, and 2.2% of gold.

With permit applications ready and a geological team identifying high priority targets, the Rocky Lake and Namew Lake projects will also see QMC becoming a crucial supplier of copper for the burgeoning EV charging infrastructure market.

Mineral development and securing a supply of raw materials is more vital than ever as we move towards another industrial revolution. Canadian hard rock lithium resources have the potential to lead North American lithium production as auto manufacturers turn production towards EVs. The internal combustion engine and its fuel, oil, are set to become relics of the past. The new fuel is lithium, and Canada is primed to lead lithium production.

Please note, this article will also appear in the ninth edition of our quarterly publication.