As MIRARCO commemorates a quarter-century of groundbreaking advancements, this article delves into their pioneering efforts in sustainable mining, blending academic rigour with industrial pragmatism.

For the last 25 years, Mining Innovation Rehabilitation and Applied Research Corporation (MIRARCO) has been a leader in developing and deploying innovative, sustainable mining solutions for the industry’s needs. MIRARCO is a not-for-profit and applied research corporation and affiliated research entity to Laurentian University in Sudbury, Ontario, Canada. We have built a solid reputation in each of our core research centres (geomechanics, rehabilitation, safety, energy, software) that we have applied to mining challenges worldwide.

Much of our ongoing focus has also been on creating a pipeline of trainees who bridge their training from academic programmes, through MIRARCO and, ultimately, into the industry. Our trainees have been exposed to state-of-the-art techniques in many fields, including training in geomechanics (ground control, mining engineering, field and laboratory technologies), safety (risk assessment at mining operations, mitigation and controls, diesel emission reduction), rehabilitation (environmental monitoring, treatment technologies, regulation, and mine site implementation), energy (renewable technologies, electrification of mine fleet), and software (software development for mine sites, scheduling, ground fracture prediction) – as diverse a set of skills as the challenges we see across the whole sustainable mining life cycle.

Bridging the innovation gap: MIRARCO’s approach to mining challenges

The driving force behind MIRARCO is its dedicated workforce made up of experienced professionals, like CEO and President Dr Nadia Mykytczuk, and students at all levels of post-secondary education.

Through our unique position as a hybrid organisation, combining academic and professional dynamics, we help advance innovative and applied research. Working collaboratively with industry, private sector, government, academia, and community stakeholders has been essential in providing effective transfer of knowledge, technology, and sustainable practices.

Looking ahead to the next 25 years, MIRARCO is poised to take on some of the many challenges the global mining industry needs to solve by necessity: mining deeper, meeting critical/battery metal demands, and decarbonising operations. Applied research is one of the essential ingredients to developing solutions in these areas, and MIRARCO’s strategic vision is to strengthen our capacity and partnerships around the world, to move research and technology from the bench and into the mines of the future – sustainable mining deeper in a low carbon, zero-waste, and electrified world.

From mine wastes to riches

Biomining technologies can help address the demand for critical minerals – by unlocking value from waste. Mine wastes in areas like Sudbury, Ontario, and worldwide contain billions to trillions of dollars in unextracted commodities. Tapping into these resources has long been a losing proposition, where it costs more to extract the metals from low-grade materials like tailings than the value of the metals themselves. But technologies like biomining can shift the economics in our favour. These technologies are not new and have been applied for decades in settings like Chile’s copper mines, but commercial applications are still considered niche. With the demand for critical minerals set to outpace demands in the coming years, biomining is being given a chance to shine.

Dr Nadia Mykytczuk is working with academic and industry partners to advance the use of microbes as low-energy catalysts to extract valuable elements, like nickel, copper, and cobalt, from low-grade mine wastes like pyrrhotite. The latest project is a collaborative effort with MIRARCO completing the pilot testing of three bioleaching solutions in partnership with the University of Toronto, Canmet Mining, and SME BacTech Environmental, with the goal of having a commercial-ready process for companies like Vale and Glencore to re-process their pyrrhotite tailings and produce battery metals. If we are to demonstrate biomining as a viable solution to re-process tailings, Sudbury is a great place to start with a minimum value of $8-10bn in Ni contained in the legacy tailings.

With support from industry and grant programs like MICA (the Mining Innovation Commercialization Accelerator network), MIRARCO is ramping up facilities and test work to support the scale-up and optimisation of these processes. Innovations like biomining are one piece of a winning flowsheet that will successfully extract value from waste while reducing or removing the legacy challenges this mine waste creates in the environment. We can’t afford to meet the demands of decarbonisation by creating new environmental problems. MIRARCO is keen to help add biomining solutions to the mining and mineral resource industry toolbox.

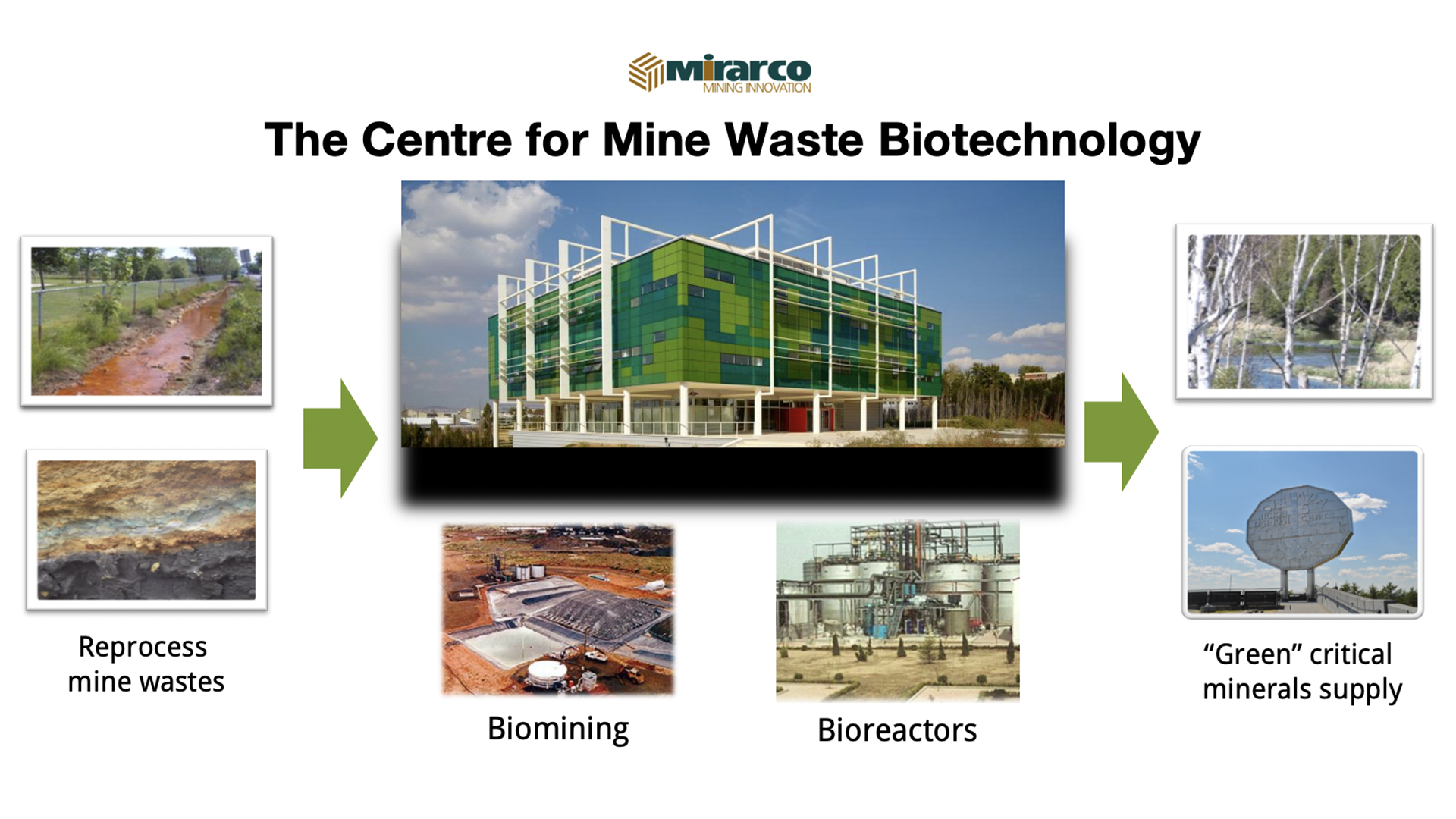

A new Centre for Mine Waste Biotechnology

Piloting facilities are needed to accelerate the commercialisation of bioleaching and bioremediation technologies for mining. Addressing the very real gap that exists between technology development and commercialisation is why MIRARCO is building a new facility to help bring new tech into the hands of the mining industry. MIRARCO is leading the development of the Centre for Mine Waste Biotechnology (the centre), which will provide the first pilot-scale facility of its kind to accelerate the commercialisation of bioleaching and bioremediation technologies in Canada. Access to this scale of technology development is crucial in bridging bench-to-market solutions and delivering a talent pipeline for the mining industry. The Centre will equip a thriving regional mining cluster (containing the highest concentration of mining talent in Canada) with the world-class tools and expertise it needs for next-generation research and development.

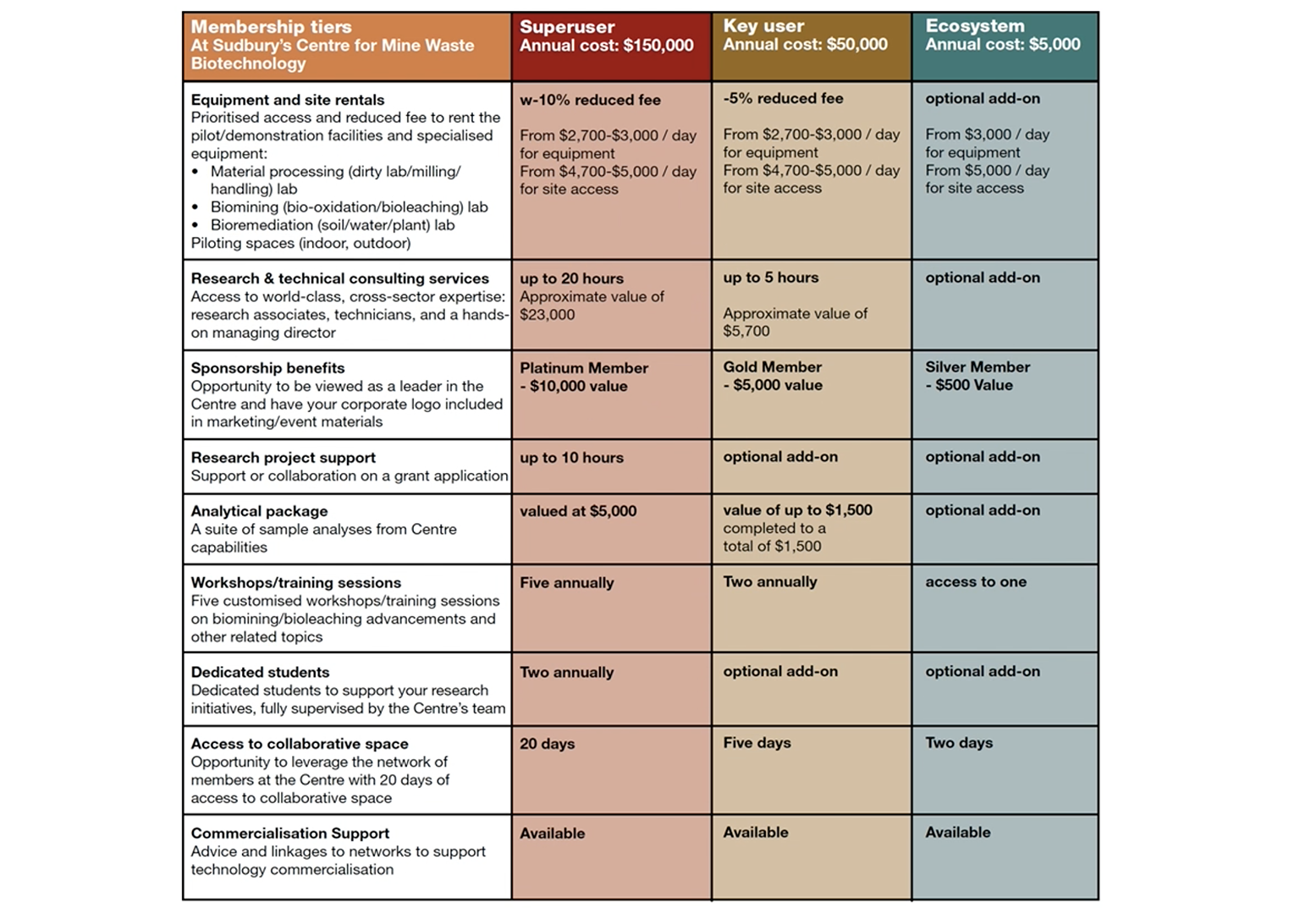

The Centre for Mine Waste Biotechnology will work to provide a 45,000-square-foot facility equipped with piloting space and equipment, along with expertise to accelerate the commercialisation of bioleaching and bioremediation technologies. MIRARCO is working to raise $38.6M in capital support to start construction of the facility in 2024, opening end of 2025. The operating model for this facility will mirror MIRARCO, a not-for-profit entity designed to engage with diverse partners to help mature different biotech solutions and accelerate IP deployment and uptake by the industry. Partnerships with industry are key to accelerating the scale-up and commercialisation of the technologies coming through the centre. As such, we have structured a membership model that will allow the industry to engage directly with Centre staff, access facilities and programming, collaborate in research projects, and access highly qualified personnel to help fill the labour shortage.

Membership tiers (Term: Three years)

Superuser membership

- Organisations that commercialise and/or implement biotechnologies

- Entities working on large or multiple projects

- Projects that require a pilot/demonstration site and/or access to specialised equipment and expertise

Key membership

- Organisations advancing research in biotechnology for mining

- Entities working on smaller projects

- Projects that require a pilot/demonstration site and/or access to specialised equipment and expertise

Ecosystem membership

- Organisations that want to be part of a unique, pilot-scale facility

- Mining stakeholders who want package flexibility

- Those who need to connect with other members and keep abreast of activities and advancements in this space

MIRARCO is poised to address industry challenges by developing new facilities like the Centre for Mine Waste Biotechnology and is keen to build partnerships across the sustainable mining industry worldwide.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.