Safesight Exploration is encouraging the mining sector to embrace the digital transformation to improve safety, sustainability, and efficiency.

In 2017, SafeSight Exploration Inc. positioned itself as a valuable partner for mining companies looking to harness the power of digital transformation for safer and more efficient operations.

What SafeSight has learned over the last six years is that safer and more efficient operations rely on accurate and available data to support effective decision-making. The company has been transformed into innovators in collecting of data in areas that would otherwise be uncollectable. Without this data, mine sites are missing the complete picture and cannot achieve a true digital twin.

“Mining must recognise that data management and data mining are the new competences and capabilities to leverage the benefits of the digital transformation.”

What is the digital transformation in the mining sector?

In the mining sector, digital transformation refers to the integration of advanced digital technologies and data-driven solutions to revolutionise traditional mining operations. This includes implementing technologies such as: Internet of Things (IoT) sensors, automation, Artificial Intelligence (AI), and data analytics that optimise processes, enhance safety, and increase efficiency. By harnessing the power of digital transformation, mining companies can improve productivity, reduce environmental impact, and make more informed decisions throughout the entire mining lifecycle.

The journey to the digital mine

In 2022 and 2023, the concept of the digital twin has quickly gained ground thanks to its potential to transform traditional mining operations. A digital twin is a virtual replica of a physical mining site, which includes equipment, geological formations, and processes, created and continuously updated using real-time data from sensors and IoT devices. This digital representation serves as a powerful tool with several key advantages that the mining industry finds immensely valuable.

First and foremost, digital twins enable mining companies to optimise their operations. They provide a detailed, real-time view of the entire mining process, allowing for the identification of bottlenecks, inefficiencies, and areas for improvement. By visualising data, companies can make more informed decisions to enhance productivity and reduce downtime.

Safety is another crucial aspect. Digital twins offer a safe environment for testing and training, allowing operators to simulate scenarios without risking lives or equipment. This enhances safety protocols, minimises accidents, and ensures a safer working environment.

Moreover, the mining industry values digital twins for their ability to facilitate predictive maintenance. By continuously monitoring equipment conditions and performance, companies can predict when maintenance is needed, reducing unplanned downtime and extending the lifespan of costly machinery.

In summary, the mining sector finds digital twins invaluable for their potential to optimise operations, improve safety, and reduce costs through data-driven decision-making, making them a pivotal part of the industry’s drive towards efficiency and sustainability.

The stages of digital transformation

As the mining sector continues its journey down the digital twin and digital transformation path, they will discover a sudden abundance of digital data generated by the host of new innovative high-tech equipment. The challenge they will face is how to effectively mine that data and extract the most valuable nuggets of information to drive intelligent decision-making and effective operations.

This is not a new problem for industries undergoing a great digital shift. In the late 90s and early 2000s, much of the public sector in Canada, specifically Ontario, engaged in the digital transformation of criminal justice. This was followed in the early 2000s by the rapid digital transformation of healthcare in the province. In both situations the pathology was identical. The stages in the pathology were as follows:

- Changing business drivers demanding technology evolution creating need and focus;

- The availability of innovative high-tech solutions to respond to the industries call to action;

- An eventual recognition of the need for highspeed robust infrastructure (5G); and

- The realisation that mining must now develop expertise in data collection, management, and data mining. These new competences and capabilities are needed to leverage the benefits of the transformation.

The exact timing of the digital transformation initiatives can vary from one mining company to another, but it’s safe to say that the broader industry began embracing these technologies in earnest around the late 2010s and continued to do so into the 2020s. This digital transformation continues accelerate and evolve as new technologies and strategies are developed and implemented to meet the evolving needs of the mining sector in a rapidly changing global landscape. As this evolution occurs the sector finds itself working through stage three and soon it will be fully immersed in stage four.

Meeting the challenges of digital data

Traditional underground data collection is limited in its reach and range and the resulting 3D models have about 30% missing details often referred to as ‘shadow.’ Shadows created in mining 3D models present several challenges for mining operations:

- Safety concerns: Shadows can obscure potential hazards;

- Planning and design: Shadows in 3D models can complicate mine planning and design;

- Exploration and surveying: Shadows can result in inaccurate or incomplete data due; and

- Maintenance challenges: Shadows can make it challenging to inspect and maintain equipment and infrastructure in obscured regions.

In short, shadows represent uncollectable data and missing data is an obstacle to safer and efficient operations impeding any hope of achieving a true digital twin.

SafeSight’s work

SafeSight Technology transforms standard operational procedures and creates safer working conditions. In facilitating that transformation, we have worked with forward-thinking global leaders in the mining sector and in doing so we have recognised that our innovations in technologies are all about sophisticated data collection.

The data collected is the raw material that fuels safer and more effective operations. Any of the numerous and quickly evolve mine planning solutions (Deswik, Datamine, MineMax etc.) are only as good as the data available, ‘garbage in, garbage out.’

Our work and technologies have all but eliminated shadow and removed ‘missing components’ that impede a true digital twin.

The latest in data collection

Survey and planning transformed

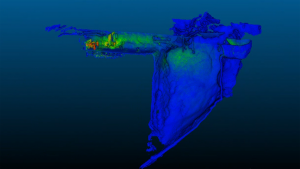

Underground mapping and modelling using SafeSight’s LiDAR collection tool set has a dramatic impact on Survey and Planning. Using SafeSight’s DB4 Underground mapping Drone, DeepTraxx RC truck and our SafeScanner removes shadows, doubles productively and creates 100% special compliance. Implementation of this data collection technology will move site closer to a digital twin without missing elements and will generate an annual $1.6m increase in production.

Mine rescue and emergency response goes digital

Emergency data no longer relies on the physical reach of the responder. SafeSight’s Emergency Response drone (ERD) and Fire Response DeepTraxx allows Responders to gather scene data and search and rescue data 200m from the incident. Responders now have remote data collection tools that include HD Video and HD Thermal imaging create digital data that will save lives.

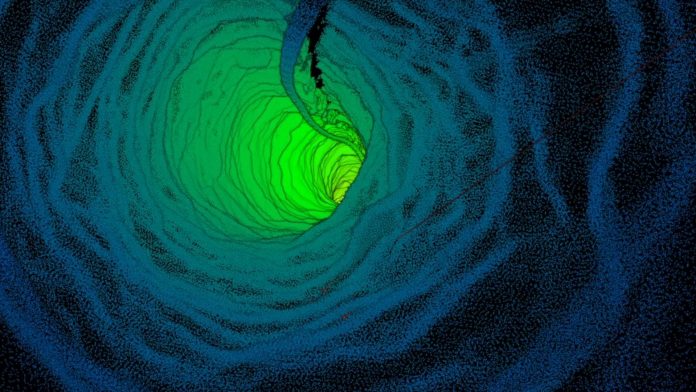

High fidelity shaft twin

The Shaft is a critical artery in any site operation. In addition, no digital twin can be complete without a digital model of the shaft. SafeSight has developed and deployed scanning technology that renders a high-fidelity 3D model of the shaft accurate to one millimetre.

Lateral mining transformed

SafeSight’s MRC Rail Runner provides the ability to autonomously collect video and a shadow free 3D model of the raise during development to help guide the rail and never miss the ore body or the target finish point. An accurate model of raises can be integrated into the digital twin all while keeping crews and survey team out of harm’s way.

The future of streaming data in mining

Mining operations are increasingly looking to move to private networks and LTE (Long-Term Evolution) technology. The shift to private networks and LTE brings numerous benefits that enhance the efficiency, safety, and overall performance of mining activities.

The migration to private networks and LTE technology in mining is driven by the need for reliable, high-performance communication, improved safety, efficient data handling, reduced downtime, enhanced security, and compliance with evolving industry standards. These technologies are becoming indispensable for mining companies seeking to modernise their operations and remain competitive in the evolving mining landscape.

SafeSight is already looking to leverage the coming infrastructure and transitioning our technology to 5G enabled data collection in Q1 of 2024. What does this translate to underground?

Survey and planning transformed

Imagine the transformation of survey, reconciliation, and mine planning if survey data collected underground was available moments after the data collection was completed. Planners and engineers would no longer have to wait for survey crews to come to surface manage and manipulate collected data to make it available for the next steps in the development lifecycle. They would have the data after the moment it was collected.

Mine rescue and emergency response

Assessing the scene

Imagine an environment where rescue or emergency data was streamed to surface in real time to provide scene assessment prior to emergency crews arriving.

Search and rescue

Imagine real time HD and thermal video stream to the command-and-control centre in an active incident come fire or search and rescue event. Experts with access to the network from any location on the globe could provide expert intelligence and incident response support. Responders could extend their reach and range far beyond any physical barrier or operating limitation.

The importance of the mining sector’s digital transformation

SafeSight will continue to push the digital boundaries in mining and support digital innovation in the sector. Digital transformation in mining holds the promise of a brighter future for the sector by revolutionising traditional practices.

It offers the potential to enhance operational efficiency, safety, and sustainability. Advanced technologies, such as IoT sensors, automation, AI, and data analytics, enable mining companies to make data-driven decisions, optimise processes, and reduce costs. Real-time monitoring and predictive maintenance minimise equipment downtime, leading to increased productivity.

Additionally, improved safety measures, including remote operation and monitoring, contribute to a safer working environment.

Furthermore, digital transformation supports environmental sustainability by reducing the industry’s ecological footprint. These technological advancements position mining on a path toward greater competitiveness and long-term viability in a rapidly evolving global landscape.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.