Scientists from Tokyo Metropolitan University, Japan, have developed a new method for making ordered nanohole arrays in metallic oxide thin films using a range of transition metals.

The team used a template to pre-pattern metallic surfaces with an ordered array of dimples before applying electrochemistry to selectively grow an oxide layer with holes. The process makes a wider selection of ordered transition metal nanohole arrays available for new catalysis, filtration, and sensing applications.

In the search for materials that are porous at nanoscale, the field of electrochemistry offers an elegant strategy: anodisation using metallic electrodes, made from aluminium and titanium, can be used to form ordered nanohole arrays in a metallic oxide layer. By getting the conditions right, these holes adopt highly ordered patterns, with tight control over their spacing and size. These ordered porous metallic oxide films are ideal for a wide range of industrial applications, such as filtration and efficient catalysis.

In their previous work, the team led by Professor Takashi Yanagishita of Tokyo Metropolitan University developed a scalable method to make ordered nanohole arrays in aluminium oxide thin films. The team’s films could be made up to 70mm in diameter, and easily detached from the substrates they are made on.

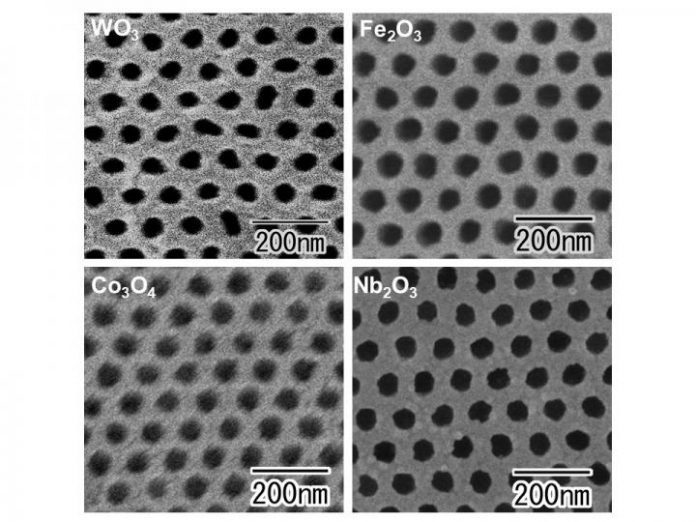

The team have now used these films to create similar patterns using a far wider range of transition metal oxides. By using the ordered nanoporous alumina as a mask, they used argon ion milling to etch ordered arrays of shallow dimples in the surfaces of various transition metals, including tungsten, iron, cobalt, and niobium. By anodising the dimpled surfaces, they found that thin metallic oxide layers formed with holes where the dimples were.

Researchers have previously made nanoscale holes in tungsten oxide films, but the holes were not ordered, with little control over their size or spacing, making this the first time ordered nanohole arrays have been made using these transition metal oxides. On top of that, by changing the properties of the mask, they directly demonstrated how they could easily tune the spacing between the holes, making their method applicable to a wide range of nanoporous patterns with different applications.