The NENU2PHAR project has developed a collection of commercial packaging applications made of PHA bioplastic originating from a sustainable and sourced raw material: microalgae.

The goal of the NENU2PHAR project is to set up a new European value chain of PHA-based bioplastic products with an acceptable end-of-life from an underutilised biological resource. This project, funded by the EU Horizon 2020 programme through the Circular Bio-based Europe Joint Undertaking (CBE JU), gathers 17 partners from both research and industry sectors to develop a new bioplastic value chain starting with CO2-capturing microalgae, and ends in various plastic packaging products. This project is ready to offer a new generation of bio-sourced and biodegradable plastic products, mainly packaging solutions, to help reduce marine litter, greenhouse gas emissions, and the EU’s dependence on imported fossil fuels.

PHA and bioplastics

Polyhydroxyalkanoates (PHAs) are a class of renewable, biodegradable, and biobased polyesters. Together with polylactic acid (PLA) and polybutylene succinate (PBS), they are considered to be a green polymer group. It is expected that PHAs could gradually replace conventional plastic materials since they have similar physicochemical, thermal, and mechanical properties to polypropylene (PP) and low-density polyethylene (LDPE), representing more than 70% of the plastic used in packaging. Depending on their chemical composition, they also feature a wide array of useful physical and mechanical properties, thus allowing for a broader range of applications. In addition, PHA presents a friendly end-of-life as they readily degrade in soil, aquatic media, and home and industrial compost.

The fact that PHAs can be obtained by a purely biotechnological process based on the fermentation of carbon-rich biomass feedstocks, such as sugars, makes them particularly attractive. Unfortunately, no sustainable value chain currently exists in Europe, and production schemes developed elsewhere appear highly questionable from an environmental and ethical standpoint. Current carbon feedstocks used as fermentation substrates are usually derived from agricultural resources, such as starch produced from maize, potatoes, wheat, and tapioca. Their diversion from food production to producing bioplastics on a massive scale would certainly imply an increase in agricultural commodity prices.

Microalgae as feedstock

At the industrial level, microalgae development allows biomass production in controlled reactors that do not require arable land, eliminating competition with traditional crop/agrifood supply systems.

Microalgae capture high quantities of CO2 and generate O2, as well as sugars and lipids, that can be converted into carbon-rich feedstock while tackling carbon neutrality goals. Microalgae production systems can be integrated with the recovery of nutrients from waste streams, thus recycling materials and energy and improving the sustainability of industrial processes.

EU-based demonstration facilities are already producing microalgal biomass from wastewater treatment processes and improving the regulation of emissions and the water quality required for discharge in water bodies. This therefore saves energy and reduces greenhouse gas emissions simultaneously.

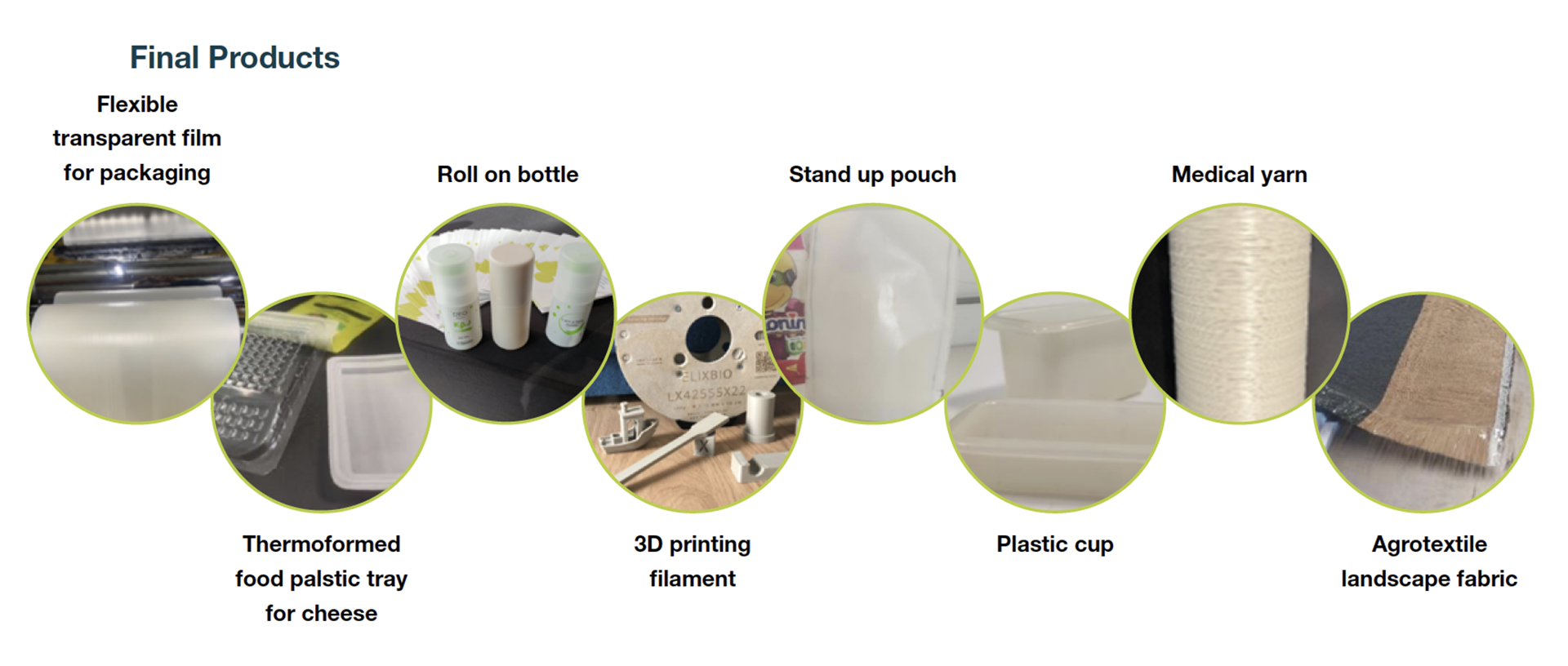

The NENU2PHAR project has developed a collection of bio-sourced and biodegradable plastics that offer a valuable alternative to non-biodegradable, petroleum-based plastics.

These plastic products are:

For food packaging:

1. Plastic trays for shredded cheese;

2. Plastic cups for compote;

3. Lid films; and

4. Stand-up pouches for yoghurt.

For other applications:

1. Roll on bottles for cosmetic packaging:

2. 3D printing filaments;

3. Medical meshes; and

4. Agrotextiles (woven groundcovers).

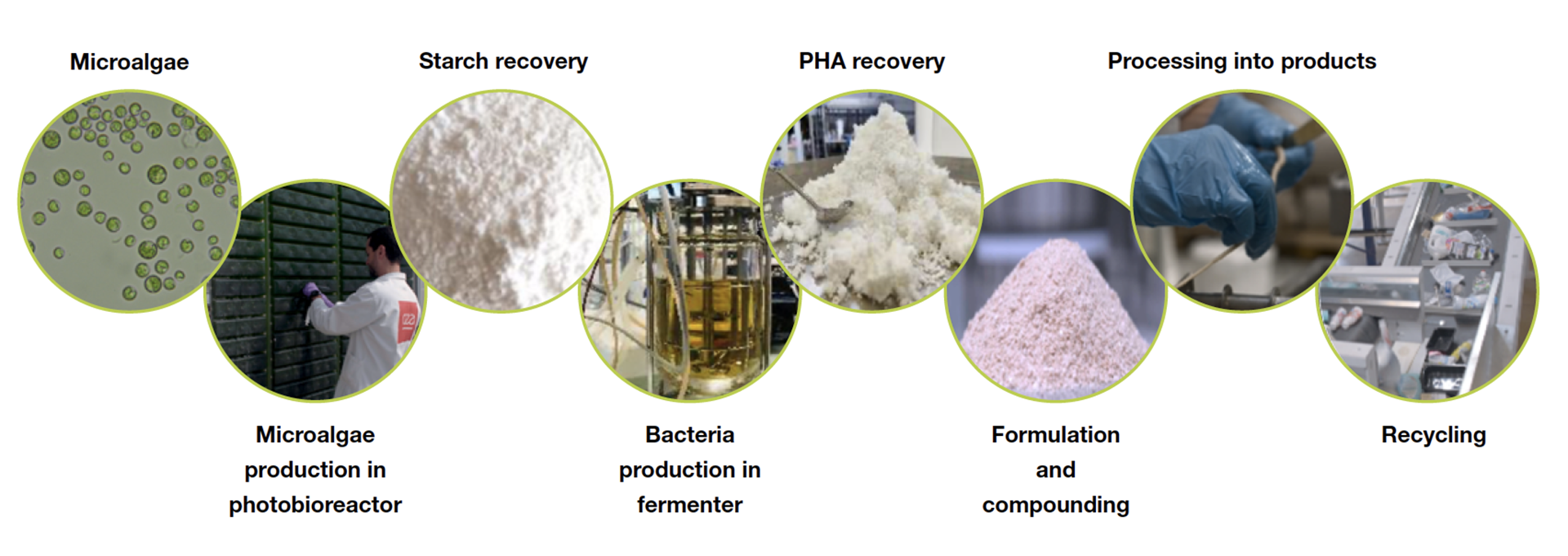

The NENU2PHAR process

- Production of microalgae, photosynthetic aquatic biomass, enhancing starch accumulation,

- Microalgae biomass refining and conversion of starch into simple sugars as glucose,

- Production of PHA by bacterial fermentation,

- Bacterial biomass refining and extraction of PHA

- Formulation, compounding and processing of PHA into new bioplastic materials,

- Development of PHA bioplastic products,

- Recycling and biodegradation of PHA bioplastic products.

Considerable efforts have been made to research and develop this innovative value chain for a more sustainable and safe bioplastic industry. The multiple steps of the NENU2PHAR value chain to produce PHA bioplastics are as follows:

The NENU2PHAR project uses recyclable materials targeting the EU’s plastic strategy objectives; once single-use plastics become waste, they must be compatible with the EU’s current recycling schemes. The NENU2PHAR project has demonstrated the feasibility of sorting PHA bioplastics using the current sorting technologies and without contamination from other plastic waste. These materials’ mechanical and chemical recycling is also possible, closing the loop of recycled plastic materials.

These recycling options are critical to diverting recyclable plastics from landfills and incineration.

Finally, experimental tests have demonstrated the biodegradability of these NENU2PHAR materials in the marine environment, targeting the EU’s objective of reducing marine litter. All the tested materials are biodegradable under industrial conditions, and some are biodegradable under domestic conditions.

Key achievements

The following NENU2PHAR project achievements can be considered the most significant and have been selected by the consortium as the most important project KER’s (Key Exploitation Results):

- Producing starch from microalgae to serve as fermentation substrate;

- Creating processes to produce and refine starch from microalgae;

- Creating fermentation processes using starch hydrolysates from microalgae as feedstock;

- Forming a methodology for PHA extraction and purification using greener solvents (compared to conventional chlorinated solvents);

- Expertise in PHA formulation and compounding;

- Building knowledge on the processes, methods and technologies for the compounding of PHA;

- Using PHA to create trays for cheese slices, cups for compote, and stand-up pouches;

- Using PHA to create pouches for wet products (yoghurt);

- Using PHA to create cosmetics packaging (roll-on bottles);

- PHA-based formulation for thermoforming with medium-high barrier properties and flexibility; and

- Recyclability (sorting, mechanical recycling, and composting) of PHA and PHA-based blends.

The NENU2PHAR project has exerted considerable efforts in the research and innovation of this value chain for a more sustainable and safe bioplastic industry. The NENU2PHAR project, especially with NENU2PHAR bioplastic products, is ready to offer technical solutions to facilitate the transition to a circular economy matching the EU’s plastic strategy and the EU’s action plan for a circular economy.

Partners of the project

This project has received funding from the Bio Based Industries Joint Undertaking (BBI-JU) under grant agreement No 887474. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Bio Based Industries Consortium.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.