Proton Ventures develops green projects and infrastructure supporting the transition to an emission-free ammonia and hydrogen industry.

Proton Ventures is an engineering solutions provider in the green ammonia industry. The company was founded in 2001 by former CEO Hans Vrijenhoef, previously the plant manager of a now defunct ammonia plant in Rozenburg, the Netherlands. In the early days, Vrijenhoef already had the vision to use ammonia as a zero-carbon fuel and hydrogen carrier. 20 years later, we see that vision becoming a reality, driven by global efforts to reduce the human impact on climate change.

Proton Ventures has its fair share of projects in this emerging landscape, ranging across scoping studies, feasibility studies, front end engineering designs (FEEDs), and engineering, procurement and construction (EPC) projects. One of the distinguishing strengths of Proton Ventures is its technology-agnostic approach as system integrator, allowing for selection of the most suitable licensors, technology providers and original equipment manufacturers for each specific project.

Green ammonia production for fertiliser applications

Green ammonia production has been a key focus throughout Proton Ventures’ two decades in existence. Instead of focusing on world-scale ammonia plants producing up to one million tonnes per annum, Proton Ventures has historically focused on modular ammonia plants with a production capacity in the range of 3-60 MT per day of ammonia. This allows ammonia plants to be located next to modular electrolysers combined with solar photovoltaic (PV) and wind capacity. The modular approach allows for improved flexibility throughout the overall ammonia plant.

Proton Ventures is currently executing an EPC project for an industrial-scale 4-MT-per-day Green Ammonia Pilot Plant (GAPP), to be built at the OCP Group chemical complex in Jorf Lasfar, Morocco. This pilot facility will consist of both a two megawatt (MW) alkaline electrolyser and a two MW proton exchange membrane (PEM) electrolyser for hydrogen production, compressed hydrogen storage, nitrogen purification, and a Haber-Bosch ammonia synthesis loop. Another key aspect of the project is the emulator that can simulate intermittent electricity profiles from any potential location in the world and feed this profile to the electrolyser system. Thus, this facility will allow for the de-risking of large-scale green ammonia facilities. After start-up, Proton Ventures will operate the facility for the first year, after which the facility will be operated by the Mohammed VI Polytechnic University, such that future engineers in the green ammonia industry will already be trained during their formal studies.

Project development for large-scale green ammonia production

Proton Ventures is also active within the TransHydrogen Alliance, which aims to produce ammonia in areas with abundant solar and wind resources, such as Brazil and Morocco, with subsequent transport and possibly cracking of ammonia to hydrogen in Rotterdam, the Netherlands. Herein, the aim is to produce ammonia on a larger scale, e.g. from one million metric tonnes per annum and beyond. The benefit of the TransHydrogen Alliance is that production and utilisation are coupled, ensuring supply while keeping the overall system cost as low as possible.

In February 2023, Casa dos Ventos and Comerc Eficiência, a renewable energy efficiency company which is part of the Comerc Energia Group, signed a partnership with the TransHydrogen Alliance. The purpose of the agreement is to enable the export of green ammonia produced in the Industrial and Port Complex of Pecém (CIPP), in the state of Ceará. The plant is to be built on a 60-hectare site with a capacity of up to 2.4 GW of electrolysis, producing 960 tonnes of hydrogen per day. With all phases implemented, the plant will produce 2.2 million tonnes of ammonia per year. The parties signed a Memorandum of Understanding to jointly develop a viable partnership targeting production of the first phase for export to Europe through the Port of Rotterdam in the year 2027.

Commercial projects like those detailed above are mainly based on available technology. However, Proton Ventures also works on innovative solutions for ammonia synthesis, such as novel electrolyser technologies, and improves ammonia synthesis technologies. Improving hydrogen production via electrolysis is key, as it typically accounts for at least 90% of the energy input for ammonia production. Proton Ventures has aided the development of the Battolyser – a combination of an iron-nickel battery and an alkaline-type electrolyser – from a university laboratory to a standalone company. Within the EU project ARENHA, Proton Ventures has also patented a low-pressure ammonia synthesis technology that can significantly improve the single pass conversion via a sorbent-enhanced separation step. The demonstration plant is currently under construction.

Ammonia storage and handling

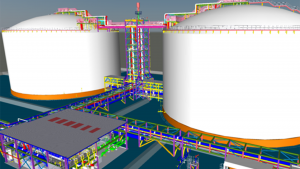

One of the most significant projects developed by Proton Ventures are the refrigerated storage tanks in Estonia (BCT) and Bulgaria (Agropolychim), which are among the largest operating ammonia storage tanks in Europe. For example, the two tanks in Estonia each have a capacity for 30 kt of refrigerated ammonia at -33°C. The tanks are double containment storage tanks complying with modern safety standards. The facilities in Estonia also consist of railcar loading and unloading systems, a marine loading arm facility, and four UAN tanks of 20 kt each. Full containment storage tanks can also be realised through Proton Ventures’ engineering and design expertise.

The global trade of green ammonia is set to expand exponentially over the coming decades, as ammonia is increasingly used as shipping fuel, stationary fuel and as a hydrogen carrier. The developments for new and improved ammonia import and export terminals to meet this need have considerably multiplied. In light of these developments, Proton Ventures and various consortium partners have received numerous contracts to design and/or construct state-of-the-art terminals around the world, for example:

- A turnkey EPC contract by OCP Group for two refrigerated ammonia storage tanks and new transfer lines in Jorf Lasfar, Morocco;

- Proton Ventures is currently conducting a feasibility study and, subsequently, the FEED for the revamping of two storage tanks and associated (off)loading infrastructure operated by Vesta Terminals in Vlissingen, the Netherlands; and

- Through the Port of Rotterdam, a feasibility study is being conducted for a new ammonia export terminal with floating port infrastructure in Oakajee, Australia.

Proton Ventures complies with state-of-the-art requirements for new green ammonia storage tanks, even when these are located in desert areas with temperatures sometimes measured in excess of 50°C. Recently, an extended FEED package was completed for a new ammonia export terminal in the United Arab Emirates. One example is a special main discharge bottom valve for inherent safety. Capital investment, spatial utilisation and simplicity are maximised using intermittent flaring and an interconnecting bridge between the two storage tanks with a combined staircase. Furthermore, the refrigeration system design is optimised for hot climate operations and a low operational cost.

Proton Ventures was also invited by VOTOB, The Dutch Association of Tank Storage Companies, to take part in the working group that will revise the PGS-12 (Publication series Dangerous Substances). The four-chair workgroup, consisting of delegates from Vopak, OCI, Yara International and Proton Ventures, will collectively improve the PGS-12, which is the subsection dedicated to ammonia storage and handling. The import of large quantities of hydrogen in the form of green ammonia is increasing the safety demands for ammonia terminals and offloading facilities in the Netherlands. Modernisation of the PSG-12 will create a clear and transparent guideline for more, larger, and safer ammonia terminals in the Netherlands.

Proton Ventures has been a proud ambassador of PGS-12 in The Netherlands and abroad, utilising the PGS-12 guideline to design safe and modern ammonia terminals in Europe, Middle East and Africa.

Nitrogen oxide emissions

When ammonia is utilised as a fuel or for nitric acid production, nitrogen oxide emissions must be mitigated. NOx emissions are mainly a local issue, causing eutrophication. On the other hand, nitrous oxide (N2O) emissions cause global warming, with a global warming potential (GWP) equivalent to 298 times that of carbon dioxide.

Nitrogen oxide emissions can be mitigated by reacting nitrogen oxides with ammonia in a selective catalytic reduction (SCR) system, resulting in the production of unharmful atmospheric dinitrogen and water. Within the EU, most nitric acid plants are equipped with such SCR systems, nearly eliminating N2O emissions from these plants. In the rest of the world, this is largely not standard practice yet, implying it is low hanging fruit in the global effort to decarbonise.

Proton Ventures was contracted as EPC contractor by Kavala Fertilisers in Greece for DeNOx and N2O reduction with an SCR system at a nitric acid plant. This DeNOx system saves about 20,000 tonnes of carbon dioxide equivalent emissions annually, while meeting the most stringent nitrogen oxide emission standards. The SCR system has also eliminated the yellow plume from the nitric acid plant.

SCR systems can also be used for ammonia conversion for energy applications, such as gas turbines and maritime engines. In fact, various gas turbines – currently fed with hydrocarbons such as natural gas – have already installed an SCR system, thus already handling ammonia onsite.

Hydrogen production

Ammonia cracking for large-scale sustainable hydrogen production

Ammonia is increasingly considered as a zero-carbon fuel and hydrogen carrier in a decarbonised energy and food landscape. As ammonia becomes more abundant as an energy vector, its use as a hydrogen carrier is set to increase. Ammonia cracking facilities for hydrogen production are currently considered in various northern European ports, such as Rotterdam and Wilhelmshaven. Proton Ventures has performed various studies on ammonia cracking for clients and remains active within various research consortia. Such centralised ammonia cracker solutions for pure hydrogen production are functionally very similar to natural gas processing plants for hydrogen production. Alternatively, decentralised ammonia cracker solutions have also been developed, which do not always require full conversion and purification of the hydrogen, thereby improving the energy efficiency of the system and the cost.

To expand Proton Ventures’ expertise in ammonia cracking, the company is currently operating a high-pressure testing facility at the high-pressure laboratory at the Technical University of Twente, the Netherlands. This is critical to validate the operational performance under industrially relevant conditions, while also allowing to test novel cracker concepts. An essential intermediate step for the industry to move toward world-scale hydrogen production facilities are industrial-grade pilot plants, as performance in terms of ammonia feedstock utilisation is key for the cost of produced hydrogen. The ammonia feedstock cost can account for over 90% of the total levelised cost of hydrogen from ammonia cracking. Thus, ensuring minimal ammonia feedstock utilisation is paramount. Building dedicated expertise at Proton Ventures with regards to efficient process and technology integration will support clients and the industry towards the lowest levelised cost of hydrogen.

Leading by example

The green ammonia economy will likely soon become a reality. Various decarbonisation projects for existing ammonia plants have already been realised, with many greenfield green ammonia plants under development or even construction, which means many consortia are in the process of commercialising ammonia energy solutions.

Proton Ventures has been at the forefront of these developments with the initiation of the annual NH3 Event in 2017, which was the first European conference focused on low-carbon ammonia production, as well as its utilisation as low-carbon fertiliser, zero-carbon fuel, and hydrogen carrier.

20 years ago, and even five years ago, only a few believed in ammonia as an energy carrier. Throughout its two decades of existence, Proton Ventures has established itself as an engineering solutions expert in the green ammonia landscape. With the same passion, the team continues to serve its clients with ammonia solutions.

Please note, this article will also appear in the fifteenth edition of our quarterly publication.