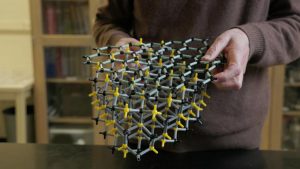

Researchers at the Georgia Institute of Technology have created the world’s first functional semiconductor made from graphene, a single sheet of carbon atoms held together by the strongest bonds known.

Semiconductors are materials that conduct electricity under specific conditions and are foundational components of electronic devices.

The team’s breakthrough in creating a semiconductor made from graphene opens the door to a new way of doing electronics.

The new research, ‘Ultrahigh-mobility semiconducting epitaxial graphene on silicon carbide,’ is published in Nature.

Graphene semiconductors could be the new way forward

Their discovery comes at a time when silicon, the material from which nearly all modern electronics are made, is reaching its limit in the face of increasingly faster computing and smaller electronic devices.

The semiconductor made from graphene is compatible with conventional microelectronics processing methods – a necessity for any viable alternative to silicon.

“We now have an extremely robust graphene semiconductor with ten times the mobility of silicon, and which also has unique properties not available in silicon,” stated Walter de Heer, Regents’ Professor of Physics at Georgia Tech. “But can we get it to work?”

He continued: “We were motivated by the hope of introducing three special properties of graphene into electronics.

“It’s an extremely robust material that can handle very large currents and can do so without heating up and falling apart.”

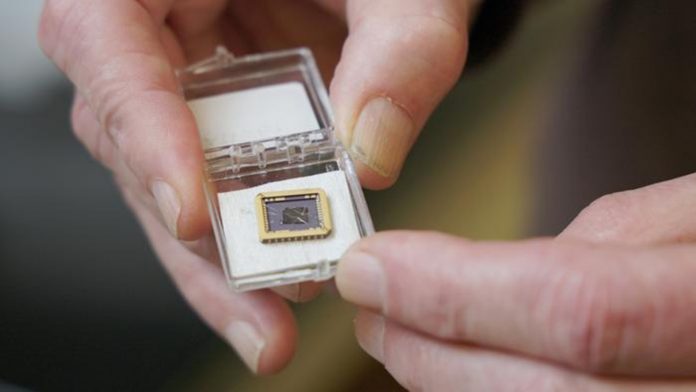

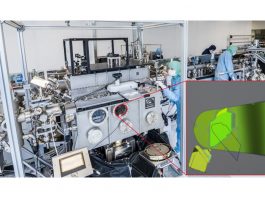

De Heer achieved a breakthrough when he and his team discovered how to grow graphene on silicon carbide wafers using special furnaces.

They produced epitaxial graphene, which is a single layer that grows on the crystal face of the silicon carbide. The team found that when it was made properly, the epitaxial graphene chemically bonded to the silicon carbide and started to create a semiconductor made from graphene.

Paving the way for the commercial use of graphene in nanoelectronics

In its natural form, graphene is neither a semiconductor nor a metal but a semimetal. A band gap is a material that can be turned on and off when an electric field is applied to it, which is how all transistors and silicon electronics work.

The major question in graphene electronics research was how to switch it on and off to work like a silicon semiconductor.

However, to make a functional transistor, a semiconducting material must be greatly manipulated, which can damage its properties. The team needed to measure its electronic properties without damaging it to prove they could produce a viable semiconductor made from graphene.

They put atoms on the graphene that ‘donate’ electrons to the system – a technique called doping used to see whether the material was a good conductor.

It worked without damaging the material or its properties.

The team’s measurements showed that their graphene semiconductor has ten times greater mobility than silicon. This means that the electrons move with very low resistance, which, in electronics, translates to faster computing.

De Heer explained: “It’s like driving on a gravel road versus driving on a freeway. It’s more efficient, doesn’t heat up as much, and allows for higher speeds so that the electrons can move faster.”

The team’s product is currently the only two-dimensional semiconductor with all the necessary properties to be used in nanoelectronics, and its electrical properties are far superior to any other 2D semiconductors currently in development.

The future of graphene semiconductors

Epitaxial graphene could cause a paradigm shift in the field of electronics and allow for completely new technologies that take advantage of its unique properties.

The material allows the quantum mechanical wave properties of electrons to be used, which is required for quantum computing.

“Our motivation for creating a semiconductor made from graphene has been there for a long time, and the rest was just making it happen,” de Heer said.

He concluded: “We had to learn how to treat the material, how to make it better and better, and finally how to measure the properties. That took a very, very long time.”