The Department of Mechanical Engineering at the University of Sheffield, UK, highlights recent developments in aviation fuel

Rigorous testing is required to ensure that any alternative, environmentally sustainable aviation fuel performs as good as or better than conventional fuels under all conditions. Only after this has been proven will the fuel be certified and supplied under the existing specifications.

Critically, this means the existing fleet of aircraft can operate on these fuels without modification, or re-certification. Such fuels are said to be ‘drop-in fuels’ in that they can be used without limitation of special procedures. Currently, the use of drop-in fuels is the only means of deployment within the aviation industry, which has to operate on a single, global fuel grade.

Aviation fuel – a brief history

Aviation fuel had not changed substantially from the 1960s until the last ten-15 years, when fuels (synthesised) from non-conventional sources were approved for use. This is despite the significant developments in engine and airframe technology and performance.

In the absence of alternatives, OEMs optimise for the global fuel quality and performance that is supplied today. The typical lifespan of an aircraft is up to 30 years, meaning that any new fuel composition needs to be backwards compatible ‘drop-in’ with existing hardware and suitable for new aircraft that may be still operating 30 years hence.

New fuel production pathways being developed offer a route to a more optimised fuel composition in the future. Typically synthetic fuels are purer than conventional refined hydrocarbons, have a lower density, burn cleaner and are more stable in the engine system at high temperatures. However, some problems with different composition, lubricating properties and physical/chemical properties limit their suitability without blending with conventional fuels.

The global aviation community has adopted a structured methodology for the assessment of technical suitability of aviation fuels from alternative sources, and this is formalised in the ASTM D4054 process. Although this is the established method for assessing the performance of different feedstocks and/or processes, this is a ‘pass/fail’ process. Blends that have so far been approved are very conservative to ensure safety, and this will remain the case until improved capability to test and predict more ‘adventurous’ blends can be approved for use.

Aviation and defence

European defence military aircraft use essentially the same technology as commercial aircraft, and with some variation, the same fuel. They too must operate safely under all conditions and on global fuels specifications when deployed so that the requirements and constraints are the same. To reduce cost and increase availability, military operators are adopting the use of commercial fuels, so the requirements for commercial and military use are converging.

Like their commercial counterparts, military users must consider environmental performance and a reduced reliance on conventional fuels as available reserves dwindle, and are often located in sensitive geographical areas outside the EU. Therefore, Europe’s defence groups have a critical role in co-ordinating, and in some cases driving, stakeholder groups to achieve the quality, performance and sustainability requirements for both commercial and military fuel use.

Controlling new blends and opening up the aviation fuel market to a wider range of fuel sources requires an improved capability to develop, evaluate and certify these blends at lower cost and timescales, and to minimise risk. The industry needs to be smarter to avoid resorting to unnecessary and very costly full- or rig-scale testing.

Research commitment

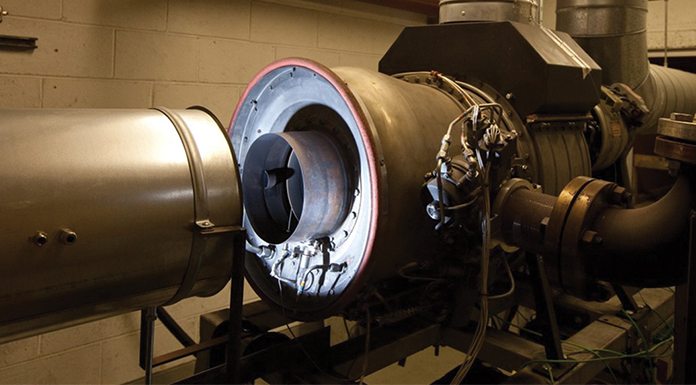

Current testing and research activities at research organisations such as the University of Sheffield’s Low Carbon Combustion Centre are focused in part around supporting the ASTM D4054 process as part of quality control and due diligence activities. Also, there is a strong commitment to the continuation of more fundamental, lower scale, research developing new feedstock to fuel routes, and also developing tools to improve the rate (and reduce cost) at which fuels can be assessed for approval, such as Jet A-1. It is highly likely that many of these research questions would be identical for the development of a fuel for other sectors as well and in the creation of a single battlefield fuel in a military environment.

Interesting research questions around the current aviation fuels specification are resulting in work which is pushing the limit of what we understand to be jet fuel. If a novel feedstock can offer a substantial benefit in terms of environmental impact, but lies outside, or on the limit of the conventional fuel Jet A-1, how flexible can we be in relaxing the specification? Clearly further work is needed. We would welcome the chance to discuss this with you if you have an interest in these developments.