The UncorrelaTEd project is working on using porous thermoelectric materials in contact with liquids to efficiently convert heat to electricity.

Try to have a look at your surroundings and check how many heat sources you can find. You will probably point first to the Sun, which radiates heat during many hours of the day. Also, the lights of buildings, which heat up under operation, as well as laptops, computers, and mobile phones. What about your own bodies? They are at around 36oC, some degrees higher than ambient temperature. There are many other examples – hot fluids in pipes, car exhaust gases, and industrial furnaces – since heat is ubiquitous.

In general, it is considered that more than 60% of the global power is lost as waste heat, which represents a huge amount of power.

A 10% recovery of this waste heat will exceed the summation of most current renewable energy sources, such as solar, wind, geothermal, and hydro energy. Hence, technologies able to convert heat to electricity can enormously contribute to solving the current energy crisis.

Thermoelectric materials directly convert heat to electricity

One of the available technologies is thermoelectric devices, which can directly convert heat to electricity under safe, clean, and environmentally-friendly operation.

When a temperature difference exists across a thermoelectric material, an electrical voltage is created, which can be converted into electricity.

The voltage that can be obtained per each degree of temperature difference is called the Seebeck coefficient, which should be the highest possible.

Apart from this parameter, it is important for a thermoelectric material to exhibit high electrical conductivity and low thermal conduction. All these three properties are strongly interrelated, which makes their optimisation difficult, and it is currently one of the main obstacles to achieving efficient thermoelectric materials.

UncorrelaTEd project: Improving the efficiency of thermoelectric devices

The UncorrelaTEd project, co-ordinated by Dr Jorge García Cañadas from Universitat Jaume I, is trying to find a solution to this problem, specifically focusing on the adverse correlation between the Seebeck coefficient and the electrical conductivity (one decreases when the other increases).

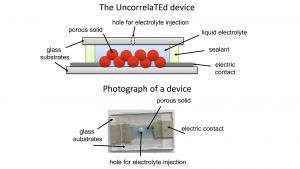

To achieve this target, a novel solid-liquid hybrid device is being developed. In this system, a porous thermoelectric material (the solid) is permeated by a liquid electrolyte (a salt dissolved in a solvent), which is designed to tactically interact with the solid to simultaneously increase the Seebeck coefficient and the electrical conductivity.

The project was built on successful initial results obtained in this solid-liquid system, which were achieved in a solid material of modest performance. For this reason, despite the significant improvements, very high overall efficiencies were not reached.

The UncorrelaTEd project aims at extending these improvements to bismuth telluride alloys, which are the best thermoelectric materials around room temperature. Apart from these alloys, the project will also look at two other families of materials: oxides and polymers, since it is expected that the project approach can be applied widely.

Although the performance is not as high as bismuth telluride, they offer different advantages, such as higher chemical stability, lower costs and higher abundance, less toxicity and flexibility, and ease of processing.

In the project, formed by six partners, three institutions work on the development of the three different families of materials (KTH in Sweden, IREC in Spain, and Specific Polymers in France). They are dealing with the challenge of preparing porous films of different materials with good initial performance, which is expected to be boosted by the presence of electrolytes. Universitat Jaume I in Spain is responsible for the integration of the solid films with the electrolytes and their optimisation, in order to provide the highest possible efficiencies. Solvionic in France contributes to the project by providing ionic liquids, which will be tested as electrolytes.

Currently, the project is intensively investigating bismuth telluride alloys and polymers. The oxides will go next.

The project’s technology could be applied to a variety of sectors

It is expected that UncorrelaTEd outcomes could be applied in many sectors. For example, the Internet of Things (IoT) development, which will lead to a new concept of society (society 5.0) with unprecedented benefits, is currently seriously limited by the use of batteries.

UncorrelaTEd technology could lead to self-powered sensors – using, for example, body heat and industrial exhausts – eliminating the need for batteries and their associated maintenance costs and harmful environmental impact.

Textiles are another sector where thermoelectric materials can be integrated into power devices such as implantable electronics and wireless monitoring systems for healthcare.

Please note, this article will also appear in the fifteenth edition of our quarterly publication.