The RESPECT project proposes an innovative solution for the recycling of different ranges of batteries to support the development of a competitive, circular, and sustainable European battery manufacturing industry.

As the European Union witnesses an unprecedented surge in the adoption of emission-free electrification, the RESPECT project emerges as a transformative force in recycling lithium-ion electric vehicle (EV) batteries. With an anticipated 30 million EVs gracing EU roads by 2030, the imperative for efficient, safe, and sustainable battery recycling processes has become more crucial than ever.

Recognising this challenge, 18 partners from nine European countries have joined forces for a ground-breaking initiative aiming to revolutionise the battery recycling process. The RESPECT project gathers multidisciplinary partners, which implies a holistic approach to addressing challenges and opportunities related to the battery ecosystem.

Coordinated by Orano Mining, the RESPECT project is funded by the Horizon Europe Research and Innovation programme and the Batteries European Partnership (BATT4EU). The project seeks to reshape the battery recycling landscape through a disruptive pre-treatment process, dual extraction routes, and a commitment to maximising material valorisation.

A disruptive method to accelerate circular economy in Europe

The RESPECT project’s primary goal is to support the burgeoning lithium-ion battery manufacturing industry. This involves creating cutting-edge green recycling materials recovery processes to enhance the European battery industry’s strategic autonomy, global competitiveness, and circularity, all embedded in a comprehensive four-year work plan.

At the forefront of RESPECT’s mission is developing a globally adaptable, flexible, and secure lithium-ion battery recycling process at the module level. This all-encompassing approach includes crucial pre-treatment steps, such as safe opening techniques, novel module deactivation, and cutting-edge technologies facilitating access to active materials. The recycling process extends to full hydrometallurgy and direct recycling, leveraging both existing and new process units. The project targets achieving a recovery rate/efficiency exceeding 90% for the overall materials and beyond 95% for critical raw materials such as nickel or cobalt by embracing innovative and sustainable developments.

The RESPECT project’s overarching ambition is to close the loop on lithium-ion battery recycling. This is to be achieved through the design, development, and implementation of green recycling processes founded on two key pillars:

Pre-treatment steps and whole hydrometallurgical approach

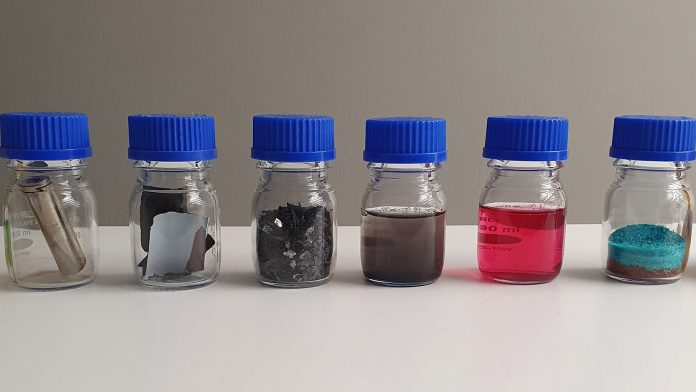

An innovative pre-treatment process, which is versatile and capable of treating varying feedstocks from End of Life modules and batteries to scraps with varying chemistries, geometries, and state of charge. The pre-treatment includes a disruptive deactivation process followed by successive separation and recovery, thus allowing the production of high-quality black mass and the recovery and valorisation of graphite, copper and aluminium. Employing full hydrometallurgical processes ensuring environmental, safety, and health considerations are paramount for the recovery from black mass and production of battery-grade salts, namely nickel, cobalt, manganese, and lithium.

Direct materials recycling route

The RESPECT project also investigates the direct recycling route of active materials. It is a novel recycling approach aimed at restoring the composition and structure of the degraded cathode material to its original state. The direct recycling route bypasses the hydrometallurgical steps and presents many advantages in terms of low CO2 footprint, reduced energy consumption and ability to recover different cathode materials.

The recycling process’s performance is validated through the manufacturing and testing of new cathode and anode materials at the cell level, which incorporate recycled materials from RESPECT processes.

RESPECT supporting new legislative requirements

To achieve climate neutrality and strategic autonomy, the EU is banking on secure access to critical raw materials (CRM), particularly critical for batteries containing materials like lithium, cobalt, and nickel. RESPECT project, in collaboration with BATT4EU, is driving R&D efforts to enhance the efficiency and cost-effectiveness of recycling technology. This mitigates supply risks and becomes a substantial economic driver for expanding battery recycling activities.

In light of the growing importance of battery recycling, the European Union has adopted a new regulation (the so-called Battery Regulation). It mandates that all collected batteries be recycled, with specific minimum levels of recycled content in new batteries. By 2031, the objectives set include a minimum of 16% recycled content for cobalt, 6% for lithium, and 6% for nickel. The RESPECT project aligns itself with these objectives, allowing the EU to become a pioneer in the decarbonisation of its road transport sector. By manufacturing and testing new cells, including recycled materials, the RESPECT project will demonstrate the achievability of the European objectives.

The RESPECT project is fully committed to the battery ecosystem

The RESPECT project strives to play a positive role in the search for sustainable battery recycling solutions. With its goals and approaches, it aims to contribute to the European battery industry and support the development of a more resilient and environmentally friendly battery supply chain. In alignment with the global shift toward a cleaner and greener future, the RESPECT project emphasises the importance of collaboration and innovation in working towards a more sustainable tomorrow.

To ensure the project stays on course and provides efficient solutions to the battery ecosystem, RESPECT has established an External Advisory Board. The respective members are SAFT, a global battery manufacturer; AKKUSER, a battery recycler; JAPIA, a Japanese automotive association; and DUPONT, an innovative technologies-based materials and solutions company. They offer valuable advice and recommendations, adding an extra layer of expertise and oversight to the project.

The RESPECT project is an active participant in the battery value chain. Together with 13 EU-funded projects, RESPECT is part of the Cluster Hub Production of raw materials for batteries from European resources. The Cluster Hub is a knowledge exchange platform where the partners of the different EU-funded projects identify common ground, discuss challenges and opportunities, and harness synergies for fostering innovations in producing raw materials for batteries in Europe. This collaborative platform has become a hub for EU-funded projects, creating a knowledge exchange ecosystem.

Moreover, on 5 October 2023, the project reached an important milestone as it had its launch event Recycling lithium-ion Batteries for Clean Mobility. The event aimed to introduce the RESPECT project to different stakeholders, the European Commission and the general public and to position it on the path to the green transition. During the event, the speakers from the European Commission, Batteries European Partnership Association, industry and EU-funded projects discussed how they can fill in the needs and requirements of the battery ecosystem and provide a solid response to the upcoming challenges.

As a partner of the Cluster Hub and organiser of the Launch event, RESPECT actively engages with stakeholders, including other BATT4EU projects, European Commission, and regulatory bodies. This proactive involvement helps the project understand the diverse needs and motivations of the battery ecosystem.

The RESPECT project stands as a testament to European innovation, collaboration, and a commitment to sustainable practices. RESPECT is positioned to significantly influence lithium-ion battery recycling going forward thanks to its creative strategies, well-aligned goals, and active participation in the battery value chain.

Disclaimer: This publication has been made following recent research results in the ‘RESPECT’, EC, co-funded research project. This project has received funding from the European Union’s Horizon Europe research and innovation program (101069865). The authors acknowledge the research outcomes of this publication belonging to the RESPECT consortium

Disclaimer: This publication has been made following recent research results in the ‘RESPECT’, EC, co-funded research project. This project has received funding from the European Union’s Horizon Europe research and innovation program (101069865). The authors acknowledge the research outcomes of this publication belonging to the RESPECT consortium

Please note, this article will also appear in the seventeenth edition of our quarterly publication.