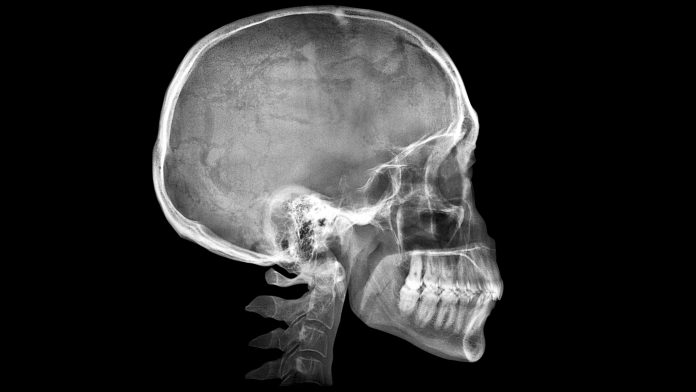

Researchers have made a skull polymer implant from polyether ether ketone, which can increase skull implant survival by up to 600%.

A team of researchers from The National University of Science and Technology MISIS (NUST MISIS) and Gamalei Institute of Epidemiology and Microbiology have developed a method of increasing the survival efficiency of skull polymer implants.

This development promotes faster recovery in patients who have had skull polymer implants and allows new bone to withstand the same loads as before the operation. An article about the research is published in Polymer Testing.

Repurposing polyether ether ketone

Polyether ether ketone is often used in polymer bone implants. This material is essential to the field as it is strong, resistant to aggressive chemical environments, wear-resistant and biocompatible.

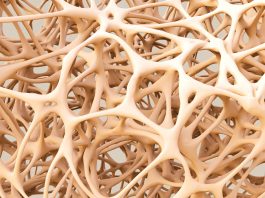

Often used in spinal surgery, polyether ether ketone is showing promise as a material tubular and as a flat bones implant. In this case, it is necessary to ensure a strong fusion of the polyether ether ketone with the patient’s bone. This fusion requires additional processing of the material to create a porous structure in which the bone tissue would grow.

The research team have now developed a combinatory approach to creating implants. The approach suggests the use of polyether ether ketone in the production of a porous implant. Researchers also explored the possibility of combining polyether ether ketone with hydroxyapatite, which is the main mineral component of bone tissue, as well as two proteins, erythropoietin (EPO) and bone morphogenetic protein BMP-2.

“First, we ground the hydroxyapatite powder into smaller particles using a planetary mill. Then it was mixed with polyether ether ketone and sodium chloride with spherical particles. Not any salt is suitable, since salt crystals can also be cubic, and this does not correspond to the natural porosity of the bone.

“After thermal pressing, the samples were washed to dissolve the salt. As the result, we had a material with 80% porosity”, comments Alexander Chubrik, one of the authors of the study.

The structure of skull polymer implants

Researchers formed the structure using salt crystals of two sizes, 106-200µm and 40-75µm. The first size allowed scientists to form pores in the material, the second created a microrelief on their surface. If the pores are needed more for the sprouting of blood vessels and bone tissue, the microrelief contributes to the attachment of osteoblasts to the surface of the implant.

“To attract osteoblasts to the implant site and induce bone growth, we saturated the samples with recombinant BMP-2 protein obtained in our laboratory. The addition of recombinant erythropoietin, also developed by us, was supposed to promote increased vascular germination and additional growth of bone tissue.

“The work on obtaining the material and characterising its properties was carried out within the framework of a project funded by the Russian Science Foundation”, comments Anna Karyagina, ScD in Biology, senior researcher at Gamalei Institute of Epidemiology.

Implanting polyether ether ketone into mice

NUST MISIS researchers implanted samples of the material into a 4mm round skull defect in eight groups of laboratory mice. Aside from the control group, the mice received samples with different composition—pure polyether ether ketone, polyether ether ketone without proteins, polyether ether ketone with different concentrations of proteins, and the same variants with the addition of hydroxyapatite.

Scientist discovered that the optimal combinations are polyether ether ketone with EPO 3.5µg, BMP-2 and 3.5µg. In these groups, the maximum overgrowth of the bone defect was achieved in six weeks of the experiment.

Due to the introduction of recombinant proteins, it was possible to increase the effectiveness of implant survival by four to six times. Not only will this new implant allow the patient to recover faster after surgery, the new bone tissue at the site of the defect would be able to withstand the same loads as before the operation.

Scientists plan to continue working on improving polymer implantation materials, for instance by using bioresorbable compounds that dissolve over time.