The SUNRISE centre (Sustainable Nuclear Energy Research in Sweden) is the first step towards building a lead-cooled research and demonstration reactor in Sweden.

The UN Agenda 2030 calls for solutions to the global climate challenge. The partners of the SUNRISE centre (Sustainable Nuclear Energy Research In Sweden) argue that this is best met by developing and deploying a combination of low-carbon power producing technologies, where nuclear power is ideal for providing reliable CO2-free base-load capacity.

In Sweden, nuclear power currently provides nearly 40% of electricity. The ongoing expansion of wind-power ties up an increasing fraction of the national hydro-power capacity in order to compensate for the intermittency of wind and solar and is therefore not as available for base-load supply.

Significant electrification and hydrogenation initiatives and strategies have been launched in Sweden in order to de-carbonise society. The current projections point to a doubling of the electricity consumption in Sweden over the coming decades.

Development of sustainable nuclear energy has the potential for game-changing positive effects on a global scale, especially with regards to clean and affordable energy for the development of sustainable climate-neutral societies. For the projected transition from fossil fuel-based transportation to electric transportation, we need to provide adequate amount of base-load electricity.

The SUNRISE centre’s work

The SUNRISE centre aims to prepare for the construction and operation of a Swedish lead-cooled research reactor with a target start date in 2030. The work in SUNRISE will not in itself be sufficient to lead to licensing and construction of a reactor, and thus it is part of a greater research and development programme with a high profile and significant commercial impact potential.

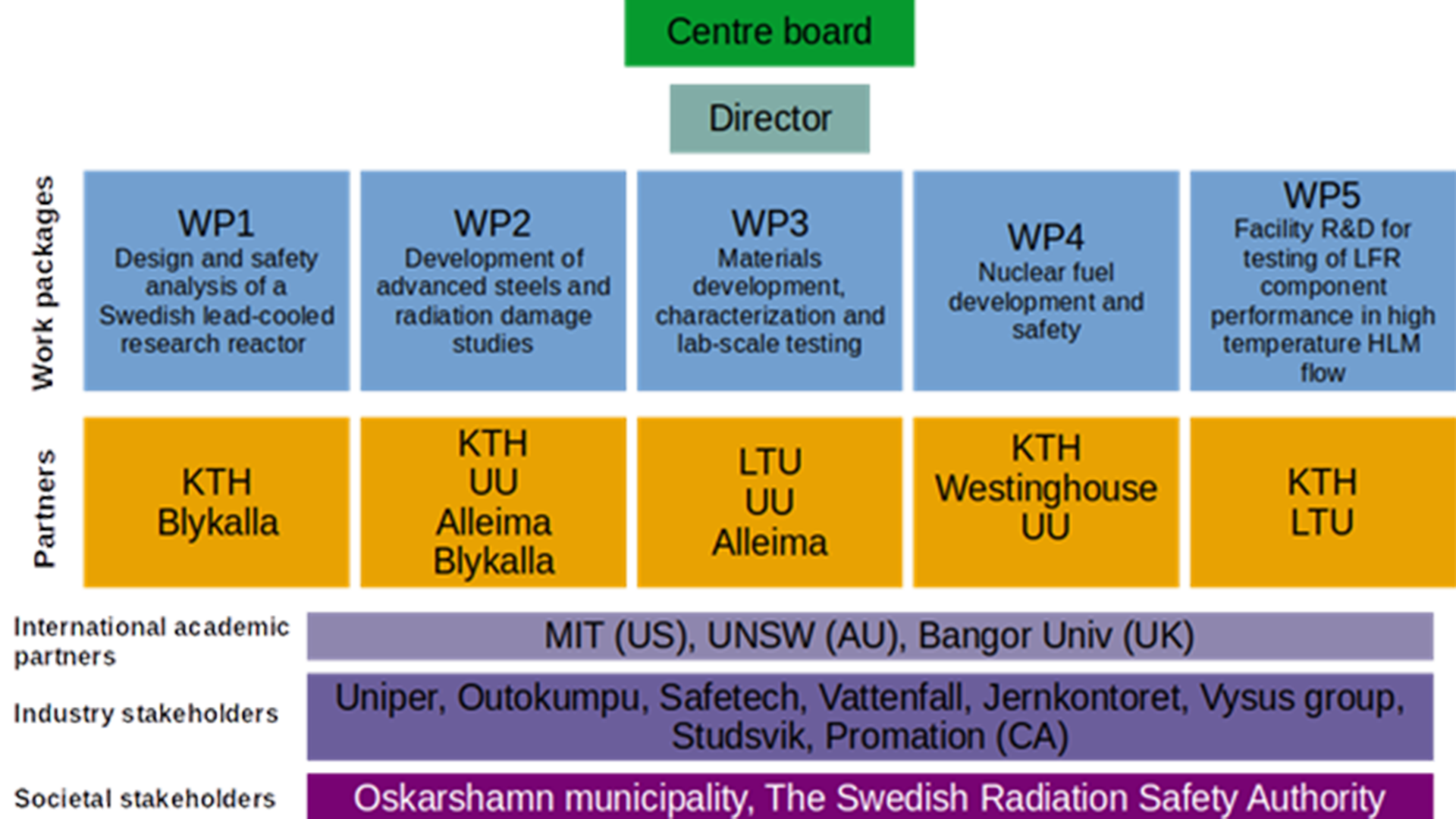

The centre gathers three universities: The centre host KTH Royal Institute of Technology (KTH), Luleå University of Technology (LTU), and Uppsala University (UU), with a wide range of industrial and societal stakeholders in five work packages. Together, these stake out the path towards advancing lead-cooled fast reactor technology in Sweden. The centre started its operations on 1 January 2021, and has since then rather closely followed the plan set out in the application to SSF.

A broad four-stage R&D programme is established by the SUNRISE centre partners which will enable Sweden to commence commercialisation of lead-cooled reactor technology within the coming ten years:

• Stage 1: Development of R&D platform for materials and components’ testing in support of design and safety analysis of a Swedish lead-cooled research reactor and an electrical mock-up prototype. (SUNRISE centre);

• Stage 2: Construction and operation of an electrically heated mock-up reactor, along with licensing of the research reactor design developed in Stage 1. (Solstice project);

• Stage 3: Irradiation testing of advanced steel composites and qualification of uranium nitride fuel (multiple projects); and

• Stage 4: Construction and operation of a lead-cooled research, demonstration, and training reactor (SUNRISE-LFR).

The research advances have so far resulted in eight peer reviewed publications and have a broad range of exciting results in the pipeline for further dissemination.

So far, 50 people have joined the centre in different capacities; 19 seniors and 26 juniors, with a mix of MSc students, PhD students, and postdocs among the juniors and a mix of professors, associate professors, researchers, and industry affiliates among the seniors.

The centre partners have already succeeded in securing funding for the second stage of the greater programme through the Solstice project application which was funded by the Energy Agency by 99 MSEK in 2022.

The SUNRISE centre has also secured the planned three-year programme access to neutron beam facilities at ANSTO in Australia in late 2022.

Additional funding has been secured for the building of local research infrastructure via cash and materials contributions from Blykalla and Alleima. KTH has provided central co-financing to the centre and Luleå University of Technology has provided co-financing for one PhD project.

Meanwhile, stages three and four are under initiating discussions with financing bodies and the Swedish regulator (SSM, The Swedish Radiation Safety Authority), as well as with industry stakeholders and government representatives. The centre is thus operating with a significantly higher budget than what was awarded by The Swedish Foundation for Strategic Research (SSF) initially.

The SUNRISE partners

The parties in SUNRISE are KTH, LTU, and UU academic partners, with Blykalla, Westinghouse and Alleima as strongly contributing industry partners. There is also an advisory body formed of other industrial, societal, and academic stakeholders. These are Uniper, Outokumpu, Safetech, Vattenfall, Jernkontoret, Vysus group, Studsvik, Promation (CA), Oskarshamns kommun, The Swedish Radiation Safety Authority, MIT (US), UNSW (AU) and Bangor university (UK). The three international partner universities are contributing in-kind to the research activities in the centre.

The SUNRISE centre and the centre staff have had a truly significant impact on the media and society. SUNRISE has been discussed in a very large number of invited popular scientific appearances, some of which are recorded and available: television and radio interviews, news articles, podcasts, a museum exhibition, panel discussions and debates, and last but not least, a highly successful YouTube channel operated by one of the SUNRISE PhD students Elina Charatsidou: ‘Elina Charatsidou – Your Friendly Nuclear Physicist’, talking to and educating the public on nuclear energy matters.

The videos related to the SUNRISE centre have over 430,000 views, and the overall channel has a reach of over 5.5 million views with nearly 80,000 subscribers after having been started in the summer of 2022. In short, SUNRISE is very visible in society.

The SUNRISE centre is led by the director, Prof Pär Olsson at KTH, together with the core group of PIs that lead the different work packages. The centre is organised according to the following organigram. To ensure a successful and efficient development of the programme, the SUNRISE centre is divided into five work packages (WP). Each WP focuses on a specific research field.

Work Package 1 (WP1): Design and safety analysis of a Swedish lead-cooled research reactor

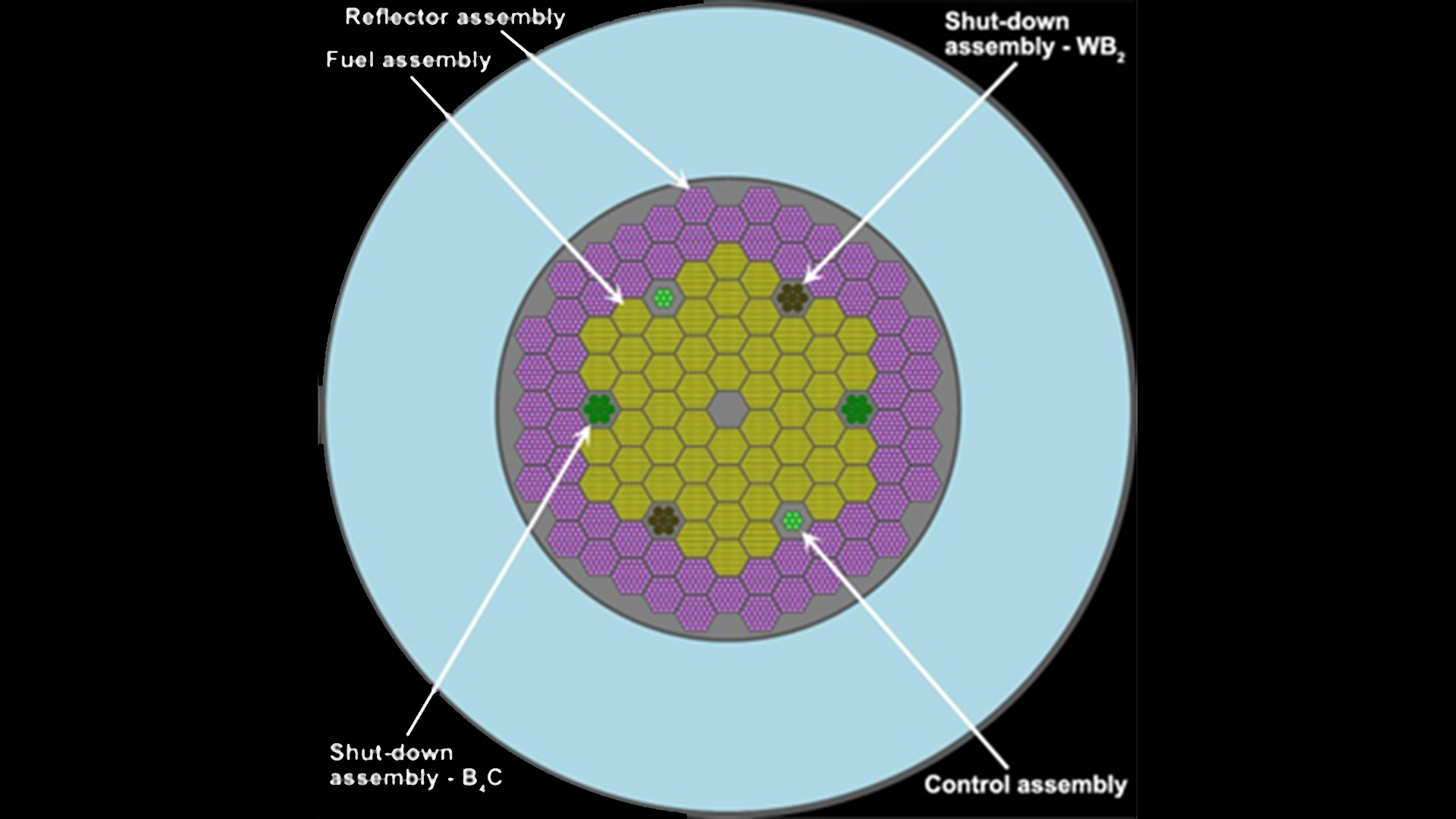

In WP1, the concept design of, and preliminary safety analysis report for a lead-cooled research and demonstration reactor (SUNRISE-LFR) to be built in Sweden must be developed and delivered. In SUNRISE WP1, the following major objectives for the research reactor, here named SUNRISE LFR, are defined as:

• Demonstrate reliable LFR operation;

• Demonstrate LFR performance under transients;

• Qualify LFR fuels (oxides and nitrides);

• Provide high-temperature steam for commercial services;

• Provide training and education of nuclear engineers;

• Provide fuel irradiation services; and

• Provide irradiation of structural materials.

The reactor is designed in such a way that any incident or accident, also known as a transient, will generate a safe and automatic response from the reactor. This is achieved using a passive safety approach, based on phenomena such as gravity, buoyancy, temperature, and radiation. Protection of the public is ensured without the need to rely on the availability of external power.

To this end, the reactor is designed with the ability to remove residual heat from the core using natural convection of the primary lead coolant, and eventually to remove heat from the primary system to the atmosphere using natural convection of air. The integrity of the barriers for the release of radionuclides, such as fuel cladding tubes and the primary reactor vessel, shall not be challenged during such transients.

Work Package 2 (WP2): Development of advanced steels and radiation damage studies

The main work in WP2 has initially focused on investigating the issue of liquid metal embrittlement (LME) on the steels developed prior to, and in SUNRISE, and the differences between liquid Pb and Pb-Bi eutectic. WP2 is focused on steel development and degradation studies – in collaboration with WP3 and WP5 – as well as experiments and modelling of radiation damage.

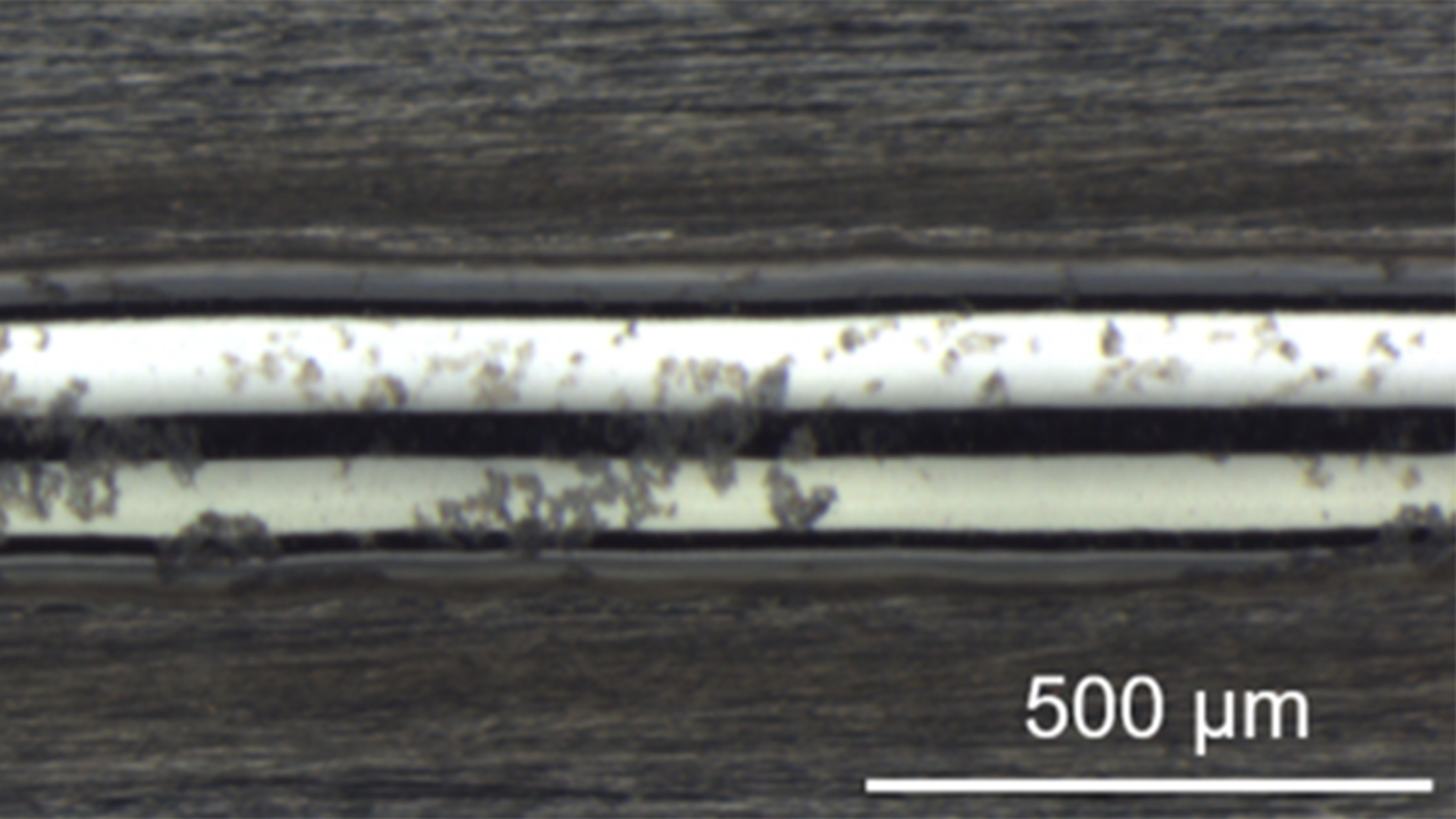

The goal is to qualify structural steels for use in the research reactor and, by extension, for use in a fleet of commercial reactors. Most materials developed and studied here will act as overlay welded corrosion and erosion protective materials, that will be fused to already qualified fast reactor materials, such as 316L and 15-15Ti. WP2 works on material selection, fabrication, and procurement, in co-operation with Alleima.

A range of experimental test matrices have been defined and are continuously refined through discussions. New steels are developed and delivered for different applications in the reactor. Exposure and mechanical stress experiments have been planned and conducted and have resulted in several publications. Selected complex components will be fabricated for testing in the experimental facilities that are constructed in WP5.

Irradiation of alumina-forming steels and subsequent characterisation and mechanical testing will be performed. Ion beam irradiation is extensively used to investigate radiation damage effects (from the Uppsala Tandem facility), exemplified by the award winning MSc diploma thesis of Gabriela Lapinska, and we are targeting access to neutron sources in terms of research reactors as well. We will work on modelling of different aspects of the steel degradation, and compare with the experiments carried out.

Work Package 3 (WP3): Characterisation, advanced manufacturing, and lab-scale testing of coatings and novel materials

WP3 is the largest work package in terms of manpower, lead by researchers from LTU. An extensive list of tasks and goals regarding materials and process development is undertaken. We will continuously work with selection of materials and components for all studies, often in centre-wide discussions at the technical workshops.

New materials are developed for different application areas in the reactor. Of critical importance is development of pump impeller materials, including hard and dense cemented carbides produced in an innovative way, coatings, and protective cladding. The processing development that is needed to fuse or clad qualified reactor materials with protective self-healing steels, will be developed here.

The main focus for such work is advanced and programmable laser welding, so that once qualified, industrial scale processing can be enabled. Local facilities at Luleå University of Technology (LTU) for wear and fretting experiments have now been adapted for use in a liquid metal environment, and testing of prototypic as well as state-of-the-art materials is underway.

All materials, compound components, weldments, and coatings are characterised with a wide range of techniques. Post-test analysis is conducted on all exposed materials and components. Selected materials and components will be prepared for testing in the larger scale facilities to be designed and constructed in WP5. Post-exposure characterisation will be mainly handled by WP2 and WP3.

Work Package 4 (WP4): Nuclear fuel development and safety

WP4 is dedicated to assessing the fuel/cladding/coolant interaction and fuel properties in operational and accident conditions. Uranium nitride is the reference long-term fuel for the SUNRISE reactor, although the initial plan is to start the reactor with oxide fuel in order to enable nitride fuel licensing in the first years of reactor operation.

By coupling experimental and modelling techniques, it will be possible to obtain a full description of this system and build a model to support the operational safety in a lead-cooled fast reactor. To achieve this, uranium nitride fuel powder and pellets will be fabricated at KTH.

With the help of additives from Uppsala University, we are making inactive simulated burn-up fuel, that chemically mimics fuel that has undergone irradiation. In order to build reliable models for fuel performance, we need to close the knowledge gaps regarding certain parameters of safety interest.

We are investigating fuel/clad/coolant interactions at different conditions including room temperature, operation temperatures, and transient temperatures. We are working on studies of how the build-up of fission products cause properties such as the thermal conductivity to evolve, how the fuel operates under irradiation, and on diffusion and release of gases into the clad.

We have prepared and sent simulated burn-up fuel samples for high-temperature neutron diffraction experiments in ANSTO, Australia. We work on ion irradiation studies of UN and simulated burn-up fuel and are developing advanced methods to measure the evolution of thermal properties under irradiation.

We work on thermodynamic modelling of the important phases that appear in the fuel/clad system and have joined the TAF-ID project. We investigate whether there is any relevant chemical fuel/clad/coolant interaction that should be modelled from the point of view of reactor safety. We will refine fuel fabrication parameters with spark plasma sintering to perfect impurities, microstructure, and porosity control.

We will perform mechanical testing and irradiation exposure of fuel materials. We will work with detailed state of the art microstructural characterisation tools in all of these aspects.

Work Package 5 (WP5): Development of experimental and modelling approaches for testing of LFR component performance in high temperature HLM flow

In WP5, the goal is to develop a combination of modelling tools and an experimental platform that can be used for simulation and testing of Flow Accelerated Corrosion/Erosion (FACE) at high temperatures for materials and components that will be used for the reactor design and the licensing process. The aim is to provide test environments suitable for model development and validation data from FACE tests of selected reactor design components in flowing heavy liquid metal at high linear flow velocities and high temperatures.

The work will progress according to a similar materials selection procedure as in the other WPs. The detailed conditions for the test facilities are converging in the centre-wide workshops. Two testing facilities are designed, modelled and about to be constructed: a Separate Effect FACE (SEFACE) facility and a Component Test Facility (CTF). The former to focus on materials’ tolerance to FACE and the second to test reactor-relevant scale components over relevant time scales and flow and temperature conditions.

The plan is to also construct model-validating minor facilities which will work with scale-prototypic fluids, and which can be well instrumented, in order to build detailed and validated models of the conditions in the actual test facilities.

Experiments will be planned and carried out and post-test examinations of different kinds will be performed, together with WP2, WP3 and WP4. All the high-temperature Pb exposure facilities are being consolidated into the central SUNRISE laboratory that is under construction at KTH.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.