Scrap aluminium can now be recycled and transformed directly into new vehicle parts, which will significantly increase electric vehicle battery range.

As well as extending electric vehicle battery range, the process reduces more than 50% of the embodied energy and over 90% of carbon dioxide emissions by eliminating the need to mine and refine the same amount of raw aluminium ore.

The already-patented and award-winning Shear Assisted Processing and Extrusion (ShAPE™) process, pioneered by the Department of Energy’s Pacific Northwest National Laboratory and Manga, collects pieces of scrap and leftover aluminium trimmings from automotive manufacturing. Then, the material is transformed into things suitable for new vehicle parts.

The most recent advancement in the process, testing the scalability for lightweight parts to increase electric vehicle battery range, is detailed in a new report in Manufacturing Letters. The new advancement reduces the cost of recycling aluminium, so manufacturers may be able to reduce the overall cost of aluminium components, better enabling them to replace steel as the largest-used material in the automotive industry.

The recycling process contributes towards sustainability efforts

“We showed that aluminium parts formed with the ShAPE process meet automotive industry standards for strength and energy absorption,” said Scott Whalen, a PNNL materials scientist and lead researcher. “The key is that the ShAPE process breaks up metal impurities in the scrap without requiring an energy-intensive heat treatment step. This alone saves considerable time and introduces new efficiencies.”

The new electric vehicle battery range developments mark the culmination of a four-year partnership with Magna, the largest manufacturer of auto parts in North America. Magna received funding for the collaborative research from DOE’s Vehicle Technologies Office, Lightweight Materials Consortium (LightMAT) Program.

Massimo DiCiano, Manager of Materials Science at Manga, commented: “Sustainability is at the forefront of everything we do at Magna. From our manufacturing processes to the materials we use, the ShAPE process is great proof of how we want to evolve and create new sustainable solutions for our customers.”

What are the benefits of using materials made from aluminium?

Aluminium is the second most-used material in the automotive industry, following steel. Because of its many advantageous components, manufacturers have increasingly sought to use aluminium more.

For one, the material is light and robust, making it vital in producing lightweight vehicles for improved efficiency, whether extending electric vehicle battery range or reducing the battery’s capacity size. While the automotive industry currently recycles most of its aluminium, it routinely adds newly mined primary aluminium before reusing it to dilute impurities.

The new process is also much quicker and more efficient than current traditions. Currently, manufacturers use a centuries-old method of pre-heating bricks to temperatures over 550°C for several hours. The pre-heating step dissolves clusters of impurities such as silicon, magnesium, or iron in the raw metal. It distributes them uniformly in the billet through a process known as homogenisation.

In contrast, the ShAPE process can achieve homogenisation in less than a second, transforming the solid aluminium into the finished product that can increase electric vehicle battery range in a matter of minutes. Moreover, no pre-heating step is required.

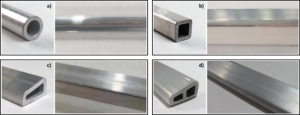

“With our partners at Magna, we have reached a critical milestone in the evolution of the ShAPE process,” said Whalen. “We have shown its versatility by creating square, trapezoidal, and multi-cell parts that all meet quality benchmarks for strength and ductility.”

ShAPE™: An innovative way of increasing electric vehicle battery range

To conduct the experiments, the researchers worked with an aluminium alloy called 6063, or architectural aluminium. This alloy is used for various applications in the automotive sector, such as engine cradles, bumper assemblies, frame rails, and exterior trims.

The research team examined these materials using scanning electron microscopy and electron backscatter diffraction, which creates an image of the placement and microstructure of each metal particle within the finished product. The results of these tests showed that ShAPE products are extremely strong and lack manufacturing defects that could cause parts failure – an extremely promising sign for increasing electric vehicle battery range.

Moreover, the products showed no signs of possessing large metal clusters – impurities that can cause material deterioration and have hampered efforts to use secondary recycled aluminium to make new products.

Now, the team is examining even higher strengths of aluminium alloys typically used in battery enclosures for electric vehicles. Whelan concluded: “This innovation is only the first step toward creating a circular economy for recycled aluminium in manufacturing. We are now working on including post-consumer waste streams, which could create a whole new market for secondary aluminium scrap.”