With the expected five-to-ten-fold increase in demand for electric vehicles in the US by 2030, the US Government is committed to establishing a domestic battery supply chain that will require a complete overhaul of the industry.

The obvious problem with this initiative is a battery supply chain barely exists in the United States today, and the majority of the focus has been on building end-value chain gigafactories, with 35 major projects currently planned or in construction, with minimal intentionality regarding essential raw materials in situ and early-stage processing.

Into the void comes US Strategic Metals (USSM), which fashions itself as a unique one-stop shop green battery metals platform willing to do the hard yards in the ground as well as take on the significant challenges of processing and recycling.

Stacy Hastie, Co-Founder and CEO, recently said: “The last time the world experienced a global energy revolution – from coal to oil – in the early 20th Century, the US was the global leader in this transition. That leadership position helped fuel the American Century and build a more stable, democratic world. Today, the stakes are just as high. America’s abundance of strategic battery metals cannot be leveraged without building a sustainable, closed-loop battery industry – the clock is ticking.”

And the point is well taken: In the race for a sustainable future, the US is currently chasing its rivals. US production of battery raw materials does not approach present domestic demand. In fact, over 90% of battery raw materials are currently sourced and processed from foreign suppliers. This problem is the result of decades of lagging investment, little domestic urgency, and self-inflicted global battery supply chain vulnerabilities. Today, there is a vital need for a secure, closed-loop battery metals sourcing, processing and recycling solutions in the US.

USSM looks to be that green battery platform that creates an end-to-end domestic producer. With a rare combination of strengths, including in-house IP and particularly flexible processing technology; expansive natural resource endowment; fortuitous location and permitting situation on a remediated site with room to grow; and an internationally experienced and highly focused team, USSM relishes the opportunity to solve the critical battery materials puzzle.

Bringing clean, ethical, low-carbon processing to the United States

As most Innovation Platform readers are well aware, cobalt (Co) and nickel (Ni) are two of the most important critical minerals required for the production of lithium-ion batteries. As of 2023, approximately 70% of the global cobalt raw material supply came from the Democratic Republic of the Congo (DRC) and approximately 40% of the global nickel supply from Indonesia. Mining practices in the DRC have become highly scrutinised globally. Indonesia, a new and growing player on the world stage for battery metals, has its own issues. In December, a tragic explosion at a smelter resulted in 18 fatalities. Neither country has a Free Trade Agreement with the United States, and both are in consideration for the list of Foreign Entities of Concern.

This leads us to the question of China, the single largest player in the industry with controlling stakes in battery metal mines around the world and an outsized role in the processing of these metals. The global supply chain for EV batteries virtually runs through China, with estimations showing that 80% of the DRC’s cobalt output is owned/controlled/processed by Chinese firms. And some 90% of all Co and Ni for Li-ion batteries destined for the US market touch China somewhere along the supply chain.

Mining and refining cobalt and nickel overseas has raised environmental, social and governance (ESG) concerns. High-Pressure Acid Leach (HPAL) and legacy Pyrometallurgy in unregulated jurisdictions contribute significantly to air and water pollution, destruction of ecosystems, infringement on indigenous rights, greenhouse gas emissions, high carbon energy use and poor working conditions. Most HPAL operations in Indonesia are coal-fed for energy, yielding up to three times more greenhouse gases, according to S&P Global.

An environmentally friendly alternative in a regulated jurisdiction is imperative, and the US Government has taken notice. The current US Administration authored two key pieces of legislation with the intent to drive the growth of domestic production of critical minerals: the Bipartisan Infrastructure Law and the Inflation Reduction Act. Additionally, the U.S. Department of Defense (DOD) has earmarked federal dollars for critical minerals in the Defense Production Act. Cobalt, nickel and lithium (Li) are among the list of strategic metals considered in the ‘National Interest’, and the money is starting to flow to new projects.

USSM is currently working with the DOD and the U.S. Department of Energy to further applications for funding from the Defense Production Act and the Bipartisan Infrastructure Law and hopes to take advantage of key portions of the Inflation Reduction Act, which will all be important to compete fairly with the many state-sponsored actors across the competitive landscape.

USSM’s unique strengths make it a global market leader in reliable, ethically sourced, and environmentally friendly strategic metals for US and global markets. USSM has a team of experienced professionals and substantial domestic resources, and through a culture of innovation, USSM is building the capacity to meet the growing needs of renewable energy industries while ensuring a reliable, domestic battery supply chain.

From humble beginnings

US Strategic Metals acquired the Madison Mine in 2018. It’s an existing private mine that operated from 1844 to 1961. In 2003, the U.S. Environmental Protection Agency. (EPA) designated the area as a Superfund site due to the erosion of waste piles or tailings from past mining and initiated clean-up efforts. As part of the acquisition, USSM partnered with local government and the EPA to execute a five-year clean-up plan from 2018.

In 2020, the geologic and block models were updated to survey mine reserves, including a pre-feasibility study on a well-drilled resource with management estimates of reserves that include historic core and churn hole data. The mine life is currently projected at 17 plus years, and is growing daily.

USSM’s business model for the site initially was to clean up and reclaim metal-rich historical tailings from the old mine and to make a mixed metal concentrate product. In 2019, USSM constructed an onsite concentrator and started successfully processing material for shipment to Canadian smelters. However, the market for electric vehicles and demand for critical battery metals forced the management team to take another look at the trajectory of the business.

Evolution of the business model: From environmental clean-up to processor/recycler

In 2020, USSM decided to create a flexible, integrated processing facility to upgrade the concentrate further.

As USSM’s background was affiliated with environmental clean-up and their governing ethos is ‘being good stewards of the land’, it made sense to pursue environmentally friendly Hydrometallurgical technology. This resulted in the construction of a pilot plant in 2021 where they tested and developed their wholly owned proprietary technology called ‘Metalox®’.

The Metalox technology produces battery-grade products with high margins and low CO2 emissions. A life cycle assessment of the technology indicates Metalox will create a meaningful improvement over the current industry standard for the targeted stages of battery materials processing and refining. In fact, Metalox is expected to produce 61% and 45% lower CO2 emissions for cobalt and nickel, respectively, versus industry benchmarks established.

But perhaps the most important virtue of the Metalox technology is its flexibility. Through three years of test work on many different feed sources, the technology has proven effective and efficient in converting solids to liquids with high recoveries. This flexibility led to the introduction of recycled battery Black Mass into the feed mix and another improvement to the flow sheet.

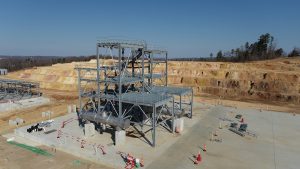

Black Mass is the new frontier in urban mining, and USSM partnered with recycling experts on a long-term feed contract, which will allow USSM to expand into the recycling business. The capital expenditure plan is completed, and construction is ongoing for a first-of-its-kind combined concentrate and recycling hydrometallurgical plant that will produce nickel and cobalt sulfate, copper cathode, and lithium carbonate.

First mover advantage is a major positive, with plans to begin commissioning through the end of the year and commercial start-up by the middle of 2025. Phase 1 is set to handle 240 tonnes per day and will yield 3,800 tonnes of Co, 21,000 tonnes of Ni and 6,400 tonnes of Cu contained metal as well as 16,000 tonnes of Lithium Carbonate after a full ramp-up in 2026.

Experienced leadership, significant funding to date and vital local support

US Strategic Metals has a particularly qualified and experienced leadership team with a track record of success in the environmental cleanup, critical minerals, battery metals, mining, and processing industry. CEO Stacy Hastie has an extensive background in environmental cleanup operations. The Board consists of industry leaders like Chairman Randy Waterfield, who was the former Chairman of YPO, and Willy Strothotte, the former Chairman and CEO of Glencore and Mike Patterson, Co-founder of HPS Investment Partners. The leadership of the technical team comes from the Mutanda mine in the DRC, which for many years was the largest cobalt mine in the world. Operations and commercial teams are run by proven operators with industry bona fide statuses from US Silica and Glencore, respectively.

On December 18 2023, USSM announced it had reached nearly $500m in funding and commitments. The most recent financings included a $230m commitment from affiliates of Appian Capital Advisory LLP with initial funding of a $120m secured term loan facility and a $70m secured royalty financing arrangement. Past funding commitments included approximately $120m from HPS Investment Partners and $50m from valuable offtake and sourcing partner Glencore International AG, all of which proved the capability to raise capital in a difficult environment.

Importantly, the state of Missouri strongly supports this project.

Mike Parson, Missouri Governor, said: “We congratulate USSM on securing this investment to expand its critical minerals recycling and processing operations in Fredericktown. Not only will this investment create good-paying job opportunities in the region, but it will also strengthen supply chains and allow Missouri and the nation to be less reliant on nations like China. The demand for domestic battery production and critical mineral exploration is on the rise, and this investment proves Missouri is well-positioned to capitalise on that opportunity and emerge as a national leader.”

Securing a more sustainable future

US Strategic Metals is committed to securing ethically sourced materials that are crucial for the national and global economy of the future. At the flagship facility in Madison County, MO, USSM is completing important environmental remediation while unlocking new economic vitality at a long-dormant site and creating stable and long-term jobs in a rural and economically challenged area for the green economy. As a company, USSM is committed to ESG:

Environmental

Committed to implementing technologies and processes that minimise the impact on the environment, such as pollution prevention measures, resource recovery activities, and other environmental best practices, such as diverting end-of-life batteries from landfills to sustainable resource recovery.

Social

Committed to the highest standards for employee health and safety and building a workplace that promotes diversity, inclusion, and respect. A promise to promote and cultivate a diverse work environment and the fair treatment of all employees by empowering a team of diverse and talented professionals from all over the world.

Governance

Committed to integrating strong governance and risk management oversight across all aspects of the business, as well as to ethical business conduct, integrity, and corporate responsibility. Creating an ethical, secondary source of critical battery materials through resource recovery as well as providing reliable and transparent data that guide mitigation strategies on risk and opportunities through the use of lifecycle and sustainable benefits assessments.

Through a combination of compelling factors: Resource endowment, clean, flexible technology, location at the centre of a robust and burgeoning battery supply chain, having permits already in place, a skilled and experienced team, and capital requirements met, USSM is ready to become the green battery platform the US needs to win the race for a sustainable future.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.