Elestor’s innovative hydrogen bromine flow battery technology offers a reliable and low-cost energy storage solution.

If anything separates people active in the world of energy storage, it is hydrogen. ‘Ideal’ and ‘necessary’ are heard just as often as ‘too expensive’ and ‘inefficient’. Be that as it may, at present hydrogen can hardly compete with batteries. At the same time, everyone can see that this is partly caused by the immaturity of the market and a lack of application possibilities. Still, hydrogen is expected to play an important role in the new energy system.

The Dutch-based company Elestor can remove an important barrier to the development of hydrogen as an energy carrier. With the integration of it’s award winning hydrogen bromine flow battery technology, it demonstrates that electrolysers, needed to produce hydrogen, can be used continuously, for long periods of time, and with cheap renewable electricity.

The economics of electrolysis

The hydrogen production costs from electrolysis are determined by the capital costs of the electrolyser, its utilisation, and the (average) electricity price during the time of operation. High electrolyser utilisation reduces the share of the electrolyser depreciation in hydrogen production costs. On the other hand, a higher utilisation increases electricity costs, as hours of expensive electricity will increasingly be included. Hence, in order to minimise hydrogen production costs, electrolyser utilisation has to be balanced with the electricity price.1

The key to reducing the cost of hydrogen production is to enhance electrolyser utilisation. This utilisation is, however, determined by the relatively short periods of time during which renewable electricity is cheap enough to economically justify producing hydrogen at a moderate energetic efficiency. In addition, an intermittent operation of electrolysers results in disproportional high costs for maintenance.

The goal is, therefore, to introduce a solution, allowing electrolysers to run continuously for long periods of time and with low-cost renewable electricity.

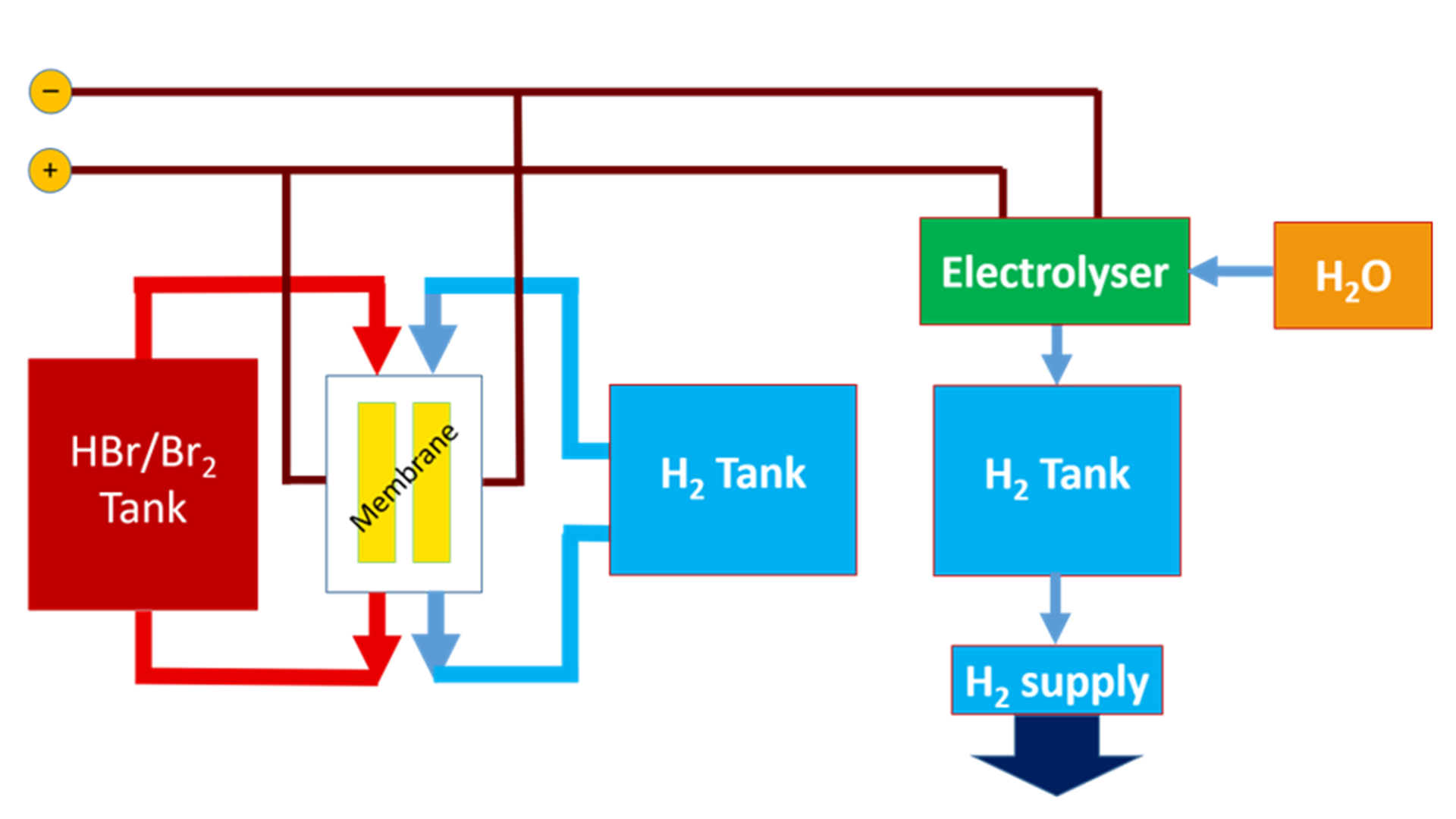

An obvious way to realise this would be to connect a battery parallel to the electrolyser. The battery stores cheap electricity to be used again by the electrolyser during periods in which the electricity from the grid is too expensive. This then increases the utilisation of the electrolyser with low-cost renewable electricity.

Purely from a conceptual point of view, any battery could, in principle, do the job. However, to also realise an economically viable solution, it is essential that the storage costs per MWh, also known as Levelized Cost of Storage (LCoS), of the battery are extremely low.

The economic breakthrough lies in using cheap energy that you get from a battery at times when energy from the normal grid is expensive. In principle, this could be done with any battery, but of course you want one whose storage cost per MWh is extremely low by nature. And that is exactly the case with the hydrogen-bromine flow battery: no other battery can store energy at lower costs per MWh.

And there is another advantage. As a direct result of the operating principle, using hydrogen as a storage medium, this technology has a special match with the production of hydrogen by electrolysis.

How does HBr flow battery technology work?

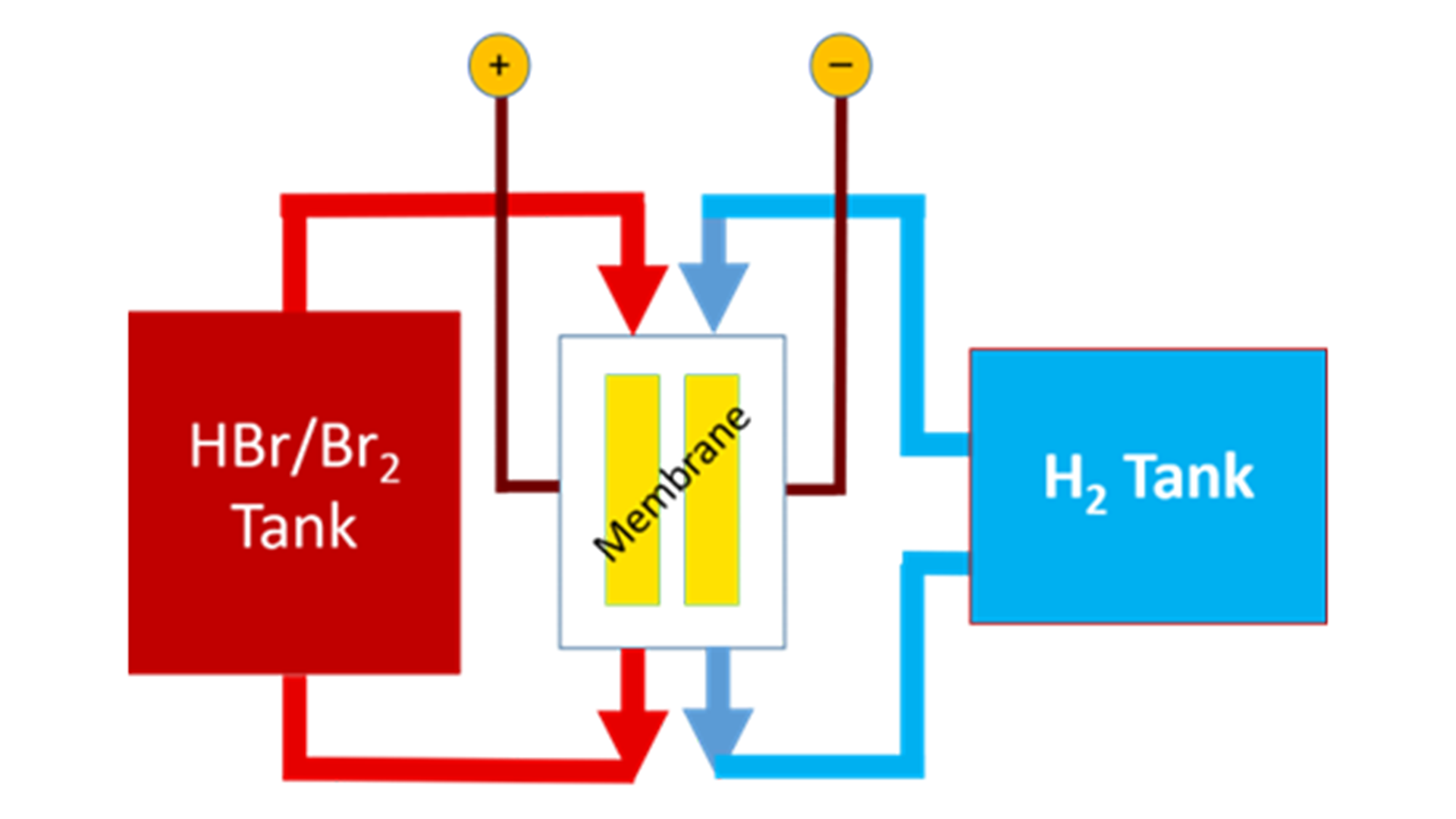

Elestor has introduced a storage technology for stationary, large-scale applications, which makes use of the flow battery principle. The diagram below shows the basic concept.

The battery consists of two large tanks to store the active materials. The red tank on the left side stores an aqueous HBr/Br2 solution, and the blue tank on the right stores hydrogen gas (H2). Bromine is, with astronomic global reserves of 100 trillion tons, abundantly available and extracted from seawater. Its availability is not geographically limited to certain regions, and therefore available at very low cost – not only today, but forever.

Each tank is part of an individual closed circuit through which the active materials flow (hence the name ‘flow battery’). The active materials flowing through the two circuits interact with each other through a membrane, which is a special layer allowing only hydrogen ions (H+) to pass through during charge or discharge.

The system is completely closed and works as any normal battery, with + and – poles for DC power connection to charge and discharge. And, like with any normal battery, nothing goes in or out – except electricity.

The required low storage cost per MWh is achieved with Elestor’s patented hydrogen bromine (HBr) flow battery technology. In addition, and due to its unique working principle using hydrogen as a storage medium, the HBr technology has a unique fit with hydrogen production through electrolysis.

In summary, the HBr flow battery:

- Generates hydrogen while charging, which is temporarily stored;

- Uses the same hydrogen again during the discharging process; and

- Does – roundtrip – not produce, nor consume, hydrogen.

The best of two worlds: A unique and cost-effective integration

Combining the best of two worlds by integrating the HBr flow battery with electrolysis results in:

In this combination:

- The electrolyser produces hydrogen whenever

renewable electricity is low-cost, due to temporary overproduction; - Simultaneously, the flow battery stores the same low-cost electricity, against the lowest possible storage costs per MWh;

- Once the price of renewable electricity increases, the electrolyser uses the in the flow battery stored electricity to generate hydrogen; and

- Once the electricity price drops again, the procedure is repeated.

Consequently:

- The flow battery bridges the periods, during which renewable electricity from the grid is expensive, with the stored low-cost electricity; and

- The electrolyser utilisation is maximised.

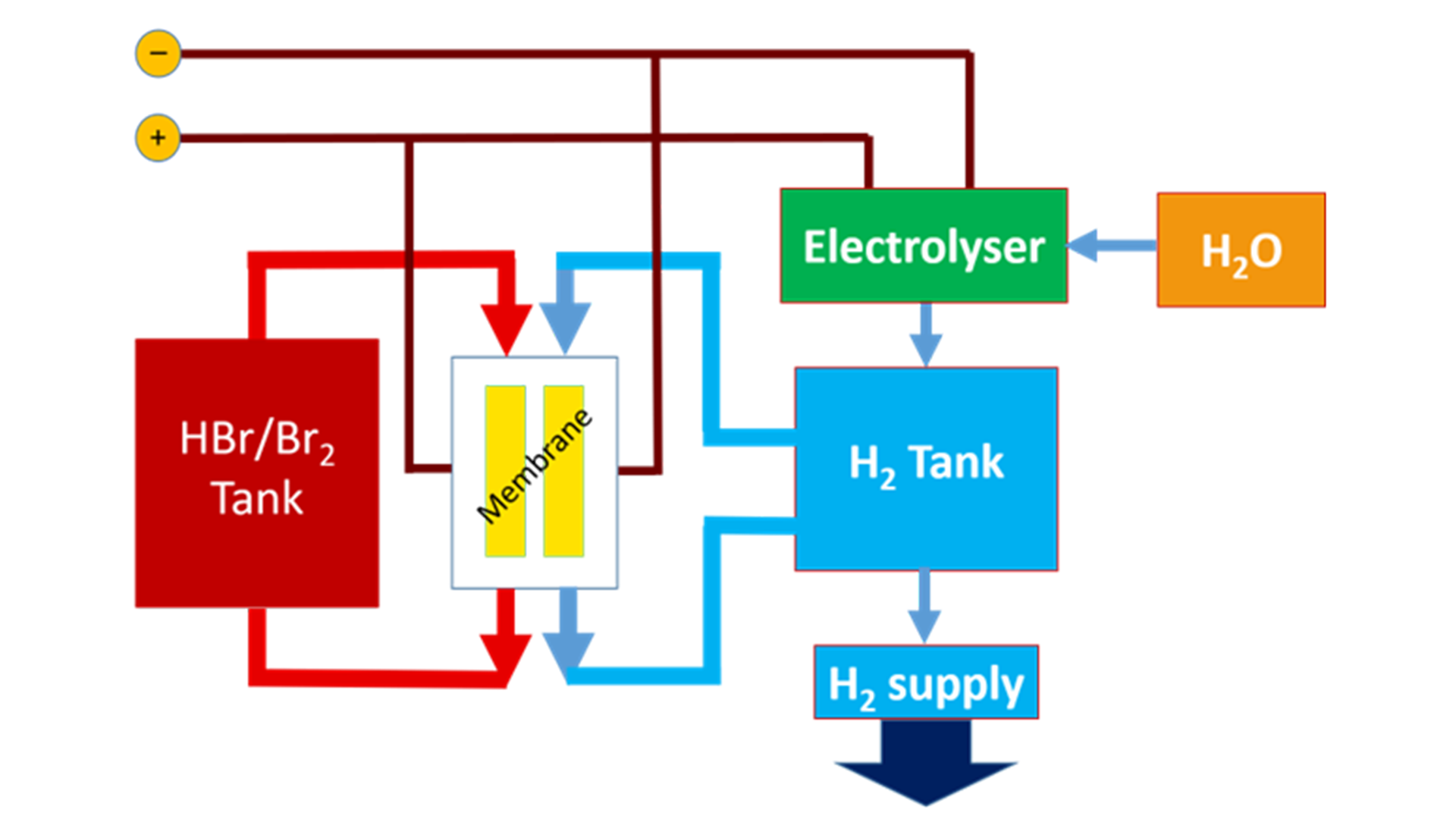

When taking a second look at the above figure, it becomes clear that both the flow battery and the electrolyser include a tank to store hydrogen. Obviously, it makes sense to combine these into one single hydrogen storage tank:

The use of hydrogen for its charge and discharge processes forms the key for Elestor’s flow battery to realise a unique and extremely cost-effective integration with electrolysers. In this way, both worlds of energy storage – with batteries and in the form of hydrogen – are integrated, which, in addition, introduces new optimisation strategies on an overall energy system level.

Above configuration leads to a number of advantages, including:

- Integration of electricity storage and hydrogen production;

- Maximise electrolyser utilisation while making use of low-cost electricity;

- Continuous hydrogen production;

- Improved electrolyser business case, reduced hydrogen production costs;

- Reduction of flow battery CapEx; and

- Further reduction of storage costs per MWh (LCoS).

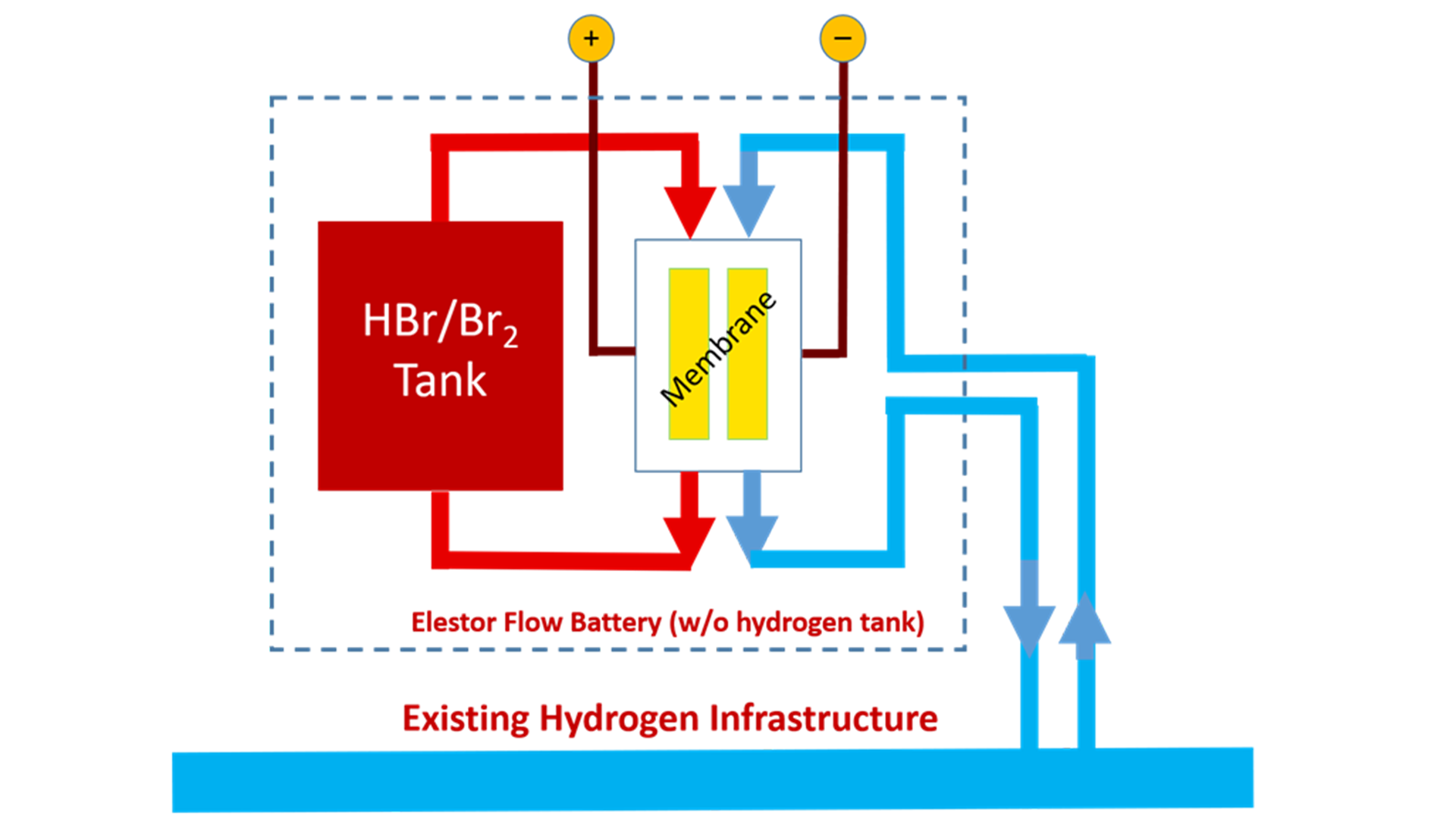

Electricity storage integrated in hydrogen infrastructures

The above applied principle unlocks other interesting and unique concepts. Apart from local storage of electricity with batteries, hydrogen is expected to play an increasingly important role in the energy transition. Hydrogen can be cost-effectively transported over long distances through pipeline infrastructures, which are constructed during the next decades on nationwide scales.

These national hydrogen backbones form a unique opportunity for Elestor’s flow battery to serve as a large storage tank for hydrogen. Since the HBr flow battery produces hydrogen during charge and uses exactly the same amount of hydrogen again during discharge, the net supply to, and consumption from, the hydrogen infrastructure is zero. Therefore, tapping into a hydrogen infrastructure does not change anything for the infrastructure itself, but it facilitates the connection of very large electricity storage systems.

The connection of Elestor’s flow battery to hydrogen backbones leads to a number of advantages, including:

- Reduction of flow battery CapEx;

- Reduction of space requirements; and

- Further reduction of storage costs per MWh (LCoS).

References

Please note, this article will also appear in the thirteenth edition of our quarterly publication.