With almost 40 years of experience with using UV technology in aquaculture, VGE makes aquaculture more sustainable with chemical-free water disinfection.

Fish are part of a healthy diet, and that is part of the reason why fish consumption has doubled over the last 50 years. To prevent overfishing, an increasing number of fish farms are being built around the world to cater for the growing demand for fish. To save water, energy, and costs, so-called ‘RAS’ (Recirculating Aquaculture Systems) are being used at fish farms. Because the water is recirculated, it must be filtered to get rid of the waste produced by the fish. Disinfection of the water is also of great importance for healthy fish, and a UV disinfection system is the best chemical free and environmentally friendly way of achieving this.

Why use UV radiation for disinfection?

Bacteria, viruses, yeasts, moulds, algae, protozoa, and parasites – micro-organisms, which are henceforth referred to as ‘MO’ – are important in many processes but can also cause food spoilage and spread disease amongst all animals, including fish.

Disinfection can be realised in several ways, such as removing, killing, or inactivation of MOs. The goal of a UV disinfection system is the inactivation of MOs. If MOs are inactivated, they cannot reproduce themselves and therefore are rendered harmless.

The reproduction process of MOs finds its origin in DNA (or RNA) replication. By damaging the thymine in the DNA or the uracil in the RNA strings through the absorption of UV-C radiation, a so-called ‘pyrimidine-dimer’ is created. If enough damage is dealt, the biological repair process cannot repair the damaged DNA or RNA, and so no reproduction takes place.

DNA and RNA absorb electromagnetic energy in the wavelength range of 200-280nm. This range is known as ‘UV-C radiation’ (sometimes referred to as ‘UV-C light’, although it is not visible to the human eye). The amount of UV-C energy required for the inactivation differs per MO. Sizing a UV system according to the application’s specific parameters will provide a reliable disinfection process.

What are the important parameters for sizing a UV disinfection aquaculture system?

There are several factors that need to be considered to correctly size the UV system. The physical water treatment is of huge importance on the effect and sizing of a UV treatment system. The filter reduces the TSS which should be < 1 FTU, and the dissolved solids are responsible for the UV transmittance of the water for UV irradiation. The lower the transmittance, the more UV power is required.

For intake water disinfection, with only one disinfection passage, the UV lamps need to irradiate all the water at once. In this case, the total suspended solids must be close to zero to maximise the disinfection effect. In a recirculation process, the water passes the UV disinfection system at a regular time interval, which reduces power consumption compared to intake water applications.

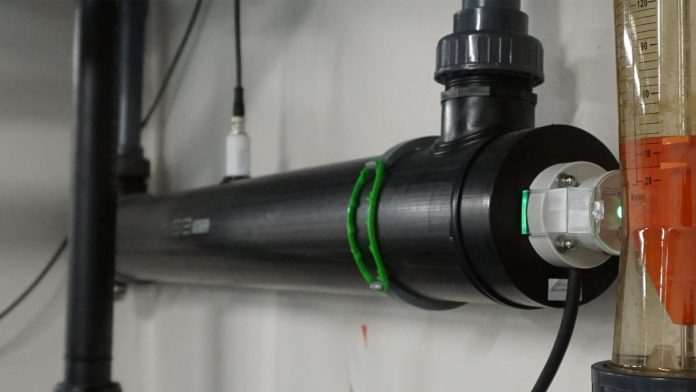

Depending on the fish farm, closed piping or open channel systems are used. The UV system must be adapted to the situation. With the VGE Pro UV systems, a closed chamber system made from stainless steel for fresh water or HDPE for saltwater applications are available. Submersible systems for installation in an open channel or tank are also available.

UV intensity sensors can be used to monitor the disinfection UV process. If the minimum required level is reached, the needed UV dose is realised.

What are the pros and cons of UV disinfection?

UV disinfection is used to control the spread of diseases caused by MOs through water. MOs attached to fish or walls will not be affected since there is no residual effect with UV disinfection.

The fish will not be harmed by the UV radiation, they are not in direct or indirect contact with the UV source in a well-designed application. Further UV disinfection is not a selective disinfection process; all MOs can be inactivated depending on the applied UV dose. This is in contrast to chemical disinfection, which can also cause (toxic) disinfection by-products which can affect the health of the fish.

UV disinfection:

- Proven technology;

- Energy efficient;

- Easy system integration;

- Fresh and salt water suitable materials used; and

- Low headloss.

Applications for aquaculture

Utilising UV technology in an aquaculture system can be beneficial in many different ways. First and foremost it is used for disinfection to keep the microbiological level under control.

In the recirculation process, the goal is to get a healthy balance between the different types of MOs that are present in the water.

When UV disinfection is used to treat intake water, the UV dose is often much higher in order to prevent foreign pathogens from entering in the RAS. These foreign pathogens can cause diseases which can result in huge financial losses for the farmer. A UV dose over 10 times what is normally recommended for RAS applications is not unlikely.

Disinfection is not the only application for UV systems. When ozone is used to improve the water conditions by oxidation, the remains of this toxic gas must be eliminated as this can cause harm to the fish. UV irradiation can destroy residual ozone in the water instantly by breaking one of the oxygen bonds in the ozone molecule.

A final method for using UV is with Advanced Oxidation Process (AOP). Using AOP in aquaculture reduces micropollutants like geosmin and MIB, which cause an off flavour in the fatty tissue of the fish. By combining with an oxidant such as hydrogen peroxide or ozone, hydroxyl radicals are formed. Hydroxyl radicals are the strongest oxidant that can be applied in water environments.

The VGE B.V. portfolio

VGE was founded in 1982 and was one of the first Dutch companies to introduce UV disinfection for the treatment of (pond) water in the Netherlands. The UV systems from VGE are used in over 60 countries in a diverse range of fish farms.

The VGE Pro UV products include a wide range of systems, but tailor-made UV disinfection systems can also be provided.

Please note, this article also appears in the sixth edition of our quarterly publication.